Check out CNCjs

I’d set $1=255…keeping it on zero can cause lost steps.

Are all axes jogging the correct direction?

What do you mean by this?

Because you don’t have homing switches, machine zero will always be wherever it is when you power on or do a hard reset.

$0=10 (step pulse, usec)

$1=255 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=7 (dir port invert mask:00000111)

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$10=3 (status report mask:00000011)

$11=0.010 (junction deviation, mm)

$12=0.002 (arc tolerance, mm)

$13=0 (report inches, bool)

$20=0 (soft limits, bool)

$21=0 (hard limits, bool)

$22=0 (homing cycle, bool)

$23=0 (homing dir invert mask:00000000)

$24=25.000 (homing feed, mm/min)

$25=500.000 (homing seek, mm/min)

$26=250 (homing debounce, msec)

$27=1.000 (homing pull-off, mm)

$100=645.000 (x, step/mm)

$101=555.000 (y, step/mm)

$102=188.976 (z, step/mm)

$110=500.000 (x max rate, mm/min)

$111=500.000 (y max rate, mm/min)

$112=500.000 (z max rate, mm/min)

$120=10.000 (x accel, mm/sec^2)

$121=10.000 (y accel, mm/sec^2)

$122=10.000 (z accel, mm/sec^2)

$130=290.000 (x max travel, mm)

$131=290.000 (y max travel, mm)

$132=80.000 (z max travel, mm)

Got it! Thanks!

Yes they are, i was able to set this in Easel when running thru setup of machine. The “Yes” & “No” sequence. They were backwards at first. this helped me hugely. i thought that was a huge battle, couple clicks and it corrected it thru Easel

What do you mean by this?

Because you don’t have homing switches, machine zero will always be wherever it is when you power on or do a hard reset.

What’s the main issue right now?

i Ran all axies from farthest point it would go side to side / up and down etc then Zero’d the machine and ran as far as i could without grinding. As i dont have homing switches to get it to stop. i thought maybe that extra info of trouble shooting would add a little to go with my settings, maybe see something im missing

my main issue is it doesnt stop at farthest point right now. when i set the home point at the left corner and set my bit. depth. when it starts up it wants to keep going it seems. its grinding and something is off. i measured everything 100 times now. im beyond annoyed at this lol i set the XYZ with a tape and ran $100-103 step/mm its good for that part. The $130-132 is set to my machine. $132 has a 8cm travel up & down. $131 a travel of 29cm & $130’s the same (guessing being sqare both numbers would be the same and on messurments for step/mm work out right) i really dont know what my issue is. but somethings not right

I also changed the values to $120-122 to 100

Yeah.

Specifically low acceleration values (10mm/ss) and during speeding up/down to feed rate (which is also slow at 500)

If the micro stepping is 1/1 this will be especially apparent.

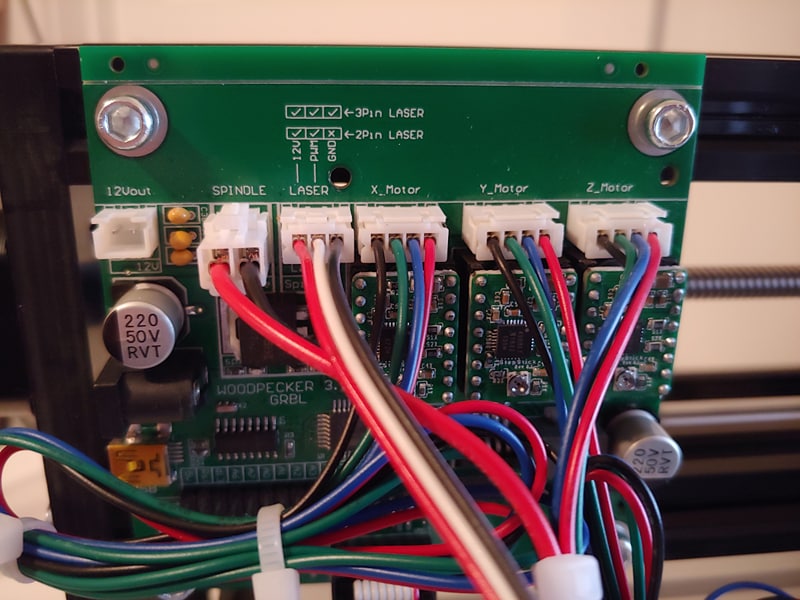

Thanks for the pictures, regarding micro step values (selected by jumpers), you need to lift out one of the steppers drivers as the jumpers are underneath. Keep machine powered OFF when taking it out/reinserting it.

1 Like

okay thanks for the tip. i have changed those values.

Thank you for the info. is this what you are looking for?

My bad, I thought for a moment jumpers were under the individual driver boards but there are none. I had a GRBL-shield once but that on had jumpers on the shield board. Dont look like the Woodpecker 3.2 GRBL have any jumpers, couldnt find reference for that online either.

But IMO our main focus here now it to get your machine to operate (move) as expected, speeds etc can be dealt with later.

- You have calibrated all axes correct? A 20mm jog command = 20mm travel?

** Regarding the “Bit broke” message from Easel in the video you posted, I dont know what trigger that / or how Easel detect such an event.

Yes all lines were calibrated, took a bit but got it

i feel like such a noob. I see now what the issue could be, my travel on the lines $130-132 were set incorrect but does it really matter if line $20-21 cant be set anyways. my travel on line:

$130= 290mm and should be $130=190mm

$131=290mm and should be $131=190mm

line $132 was correct… does this even make a difference?

Also the bit broke error was using a cheap bit on hard arcrlic and looks like it wore out 2/32 or something

The values set for $130-132 have no purpose as long as $20=0.

As long as you dont have homing switches installed leave it as-is.

Regarding “bit broke” message in the video, this came up when you were carving air?

That was my impression from the video.

1 Like

i think that error was from before, when i force stopped the machine, the error came up, it was same error as i had from the previous cut i guess

im getting this error now. must have been from pulling the “jumper” (or i believe thats what it was called)

Not sure its the case but Easel and UGS cant both be used as each tie up a com-port, blocking for the other. So completely close down either UGS or Easel when you want to use the other.

yeah no programs are open. seems since i pulled that motor piece out its all funky. port opens then closes. what a struggle. Ports not even recognized when plugging it in. Ill take a look at it in the morning. Im obviously missing something here

I’m guessing that is not an error as much as a choice when reporting an error. @JamieWalsh must have selected it. I would have a new level of respect for Easel if it could detect bit breakage.