I have a project that requires cuts from two different bits. first bit 60 varve, second 1/32 fishtail DC. I carved my first part completely took 2.5 hours. I switched the bit out then re probed, then clicked previous XY point hit start and second part of the cut ended up being 3.5 inches out… Am i doing something wrong?

Hi Cory, Welcome to the forum!

that sounds like the machine moved during the bit swap.

What model cnc is this?

Is the cnc setup to lock the stepper motors during a bit swap? (if it’s an Xcarve, the most common cnc referenced on this forum, then you’d want to do this: How to fix X-Carve Lock Motors Fault For Stress Free Bit Changes - YouTube )

Cory, this may be slightly off subject, but did your two bit carve show the two different bits (paths) in the simulation? I haven’t even set my machine up yet, but I’ve been playing around in easel and I can only get one bit’s simulation to show and from everything I’ve read, it sounds like it’s kind of automatic once you set it to use two bits. Looks like it’s supposed to show two sets of colors for the paths, but mine isn’t.

hey Seth.

Its the Xcarve. No it is most likely not setup to lock for bit swap, I don’t remember setting that up at all, i will look into this.

Ill check out the video.

I did this same cut two days ago and it went flawlessly I just don’t know why this one did what it did. I managed to fix it by starting the cut then pausing it and ever so gently adjusting the board to align with it, which is sketchy but seems to be all back in line just annoying.

thanks for the video

well i use two different carve boards you create. Im not sure if that’s the correct way or not but works fine.

Ok, I do have this set up too, but I’m thinking I want both paths on one design. I’ll keep messing with it. In my mind, these different boards should cut in exactly the same spot as long as it’s copied over, is that what you’re finding?

I feel the same though, if it works for you that’s what you do!

technically yes. I did two days ago it it turned out flawlessly

Can you share the project that isn’t showing both bits? If the project is not working properly that’s one thing, If it’s not then I’ll make a short video and show the 2 bits toolpaths separately.

Go to Project>Share and change the project to “unlisted” and then copy that link… then I can see all of the project settings…

Hey Seth

better late then never still interested in trying to figure this out.

Let me know if you have issue with the link.

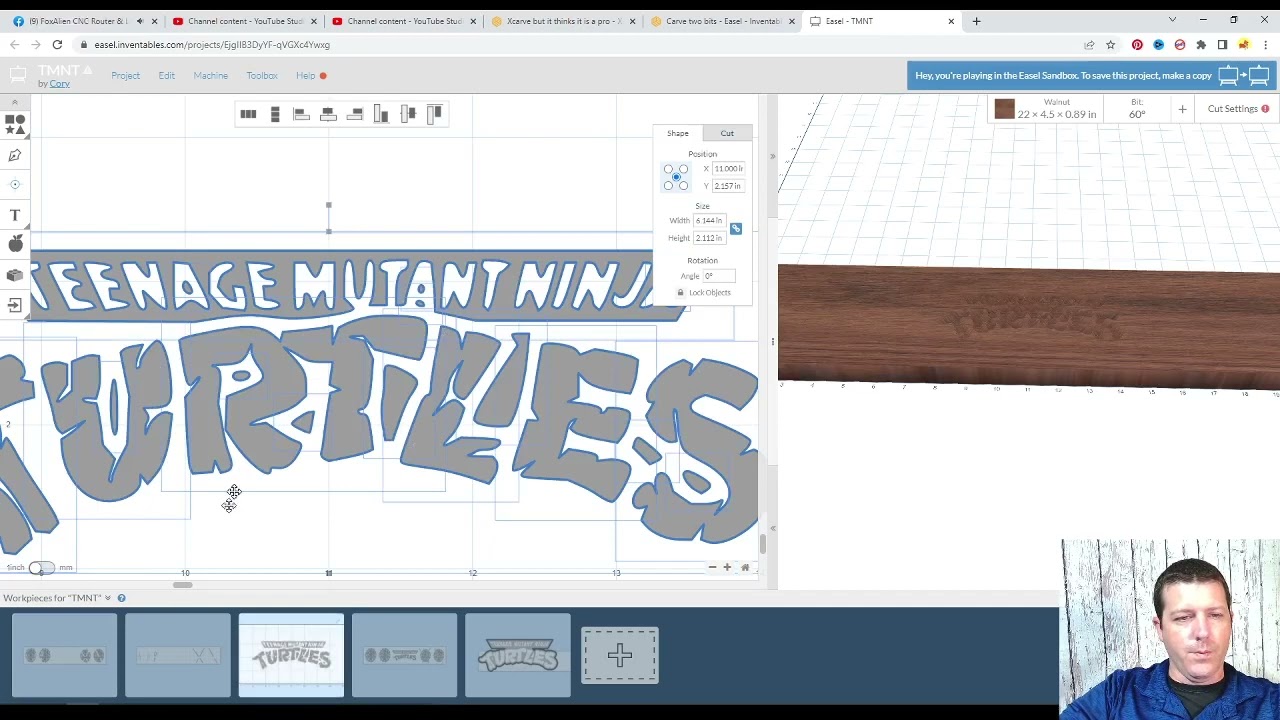

https://easel.inventables.com/projects/EjgIIB3DyYF-qVGXc4Ywxg

Well, I was actually asking Vanessa for her project, yours looked like it was setup well enough ![]()

BUT since you provided the link and wanted my input, I made a little video of what I might change (mostly cause I knew I had a clean logo) . . .

Here is the video:

Here is the Easel Project: (I think I went too fast for easel to auto save to it was not letting me save at the end, so all of the bit settings of this project are not right, you’d want to set those up correctly for yours, but at least I was able to copy over the different design with the shallower depth for the shells, the combined parts, and my version of the TMNT logo)

Hey Seth!

Wow I never expected a 18 min tutorial, amazing. I learned a lot just from that.

Yeah for sure that was an image trace. I was trying to find a svg file of one but I just ended up with the image trace one. I Like what you did with the logo there. I will work with this. My end goal was to fill it in with epoxy that’s why I had it so deep in the shell part, I did get one shell done and filled with epoxy, thought it was a bit too deep so I will adjust some of those depths.

Again thanks for showing me all that that’s awesome.

Cory

This topic was automatically closed 90 days after the last reply. New replies are no longer allowed.