Hey Guys,

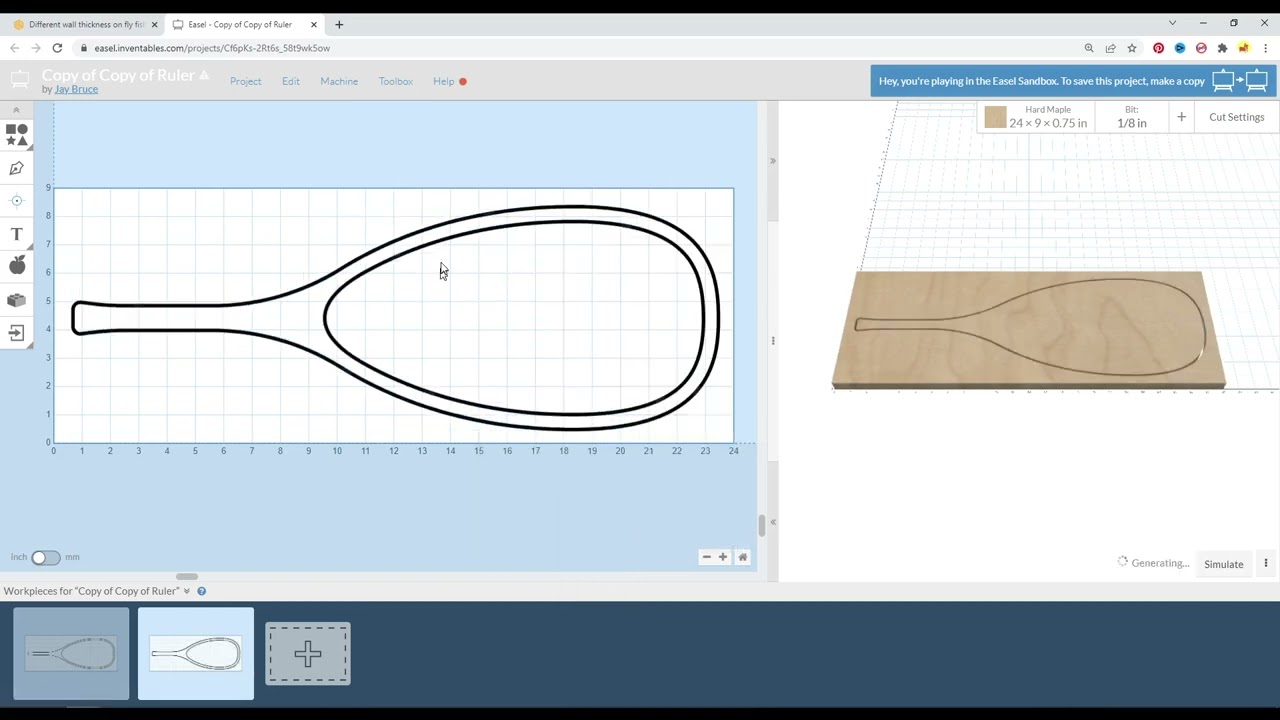

I cut out a landing net and it looks awesome. But, I noticed that the left side of the net was cut with a thinner wall than the right side. What might have been the cause of this?

Loose Vwheels & loose belt…or the project itself

Thanks man!

Do you have any idea why it makes me choose 1/8 bit size for this cut? If I choose a smaller bit, my image disappears on the cutting surface in Easel. I have to choose 1/32 to make it work but I could obviously use 1/16 or 1/8 to cut this shape I feel.

Thanks!

Justin

After you tighten your machine, I would double check your cut setting.

make sure you’re cutting inside of your inner vector and outside of your outer vector profile cutout.

also, add some tab to hold your project together until complete.

How do I make sure I am cutting on these sides of the vector? I noticed on my last landing net project that the bit would make two passes, one just a little wider that the first to cut out a thicker line. I just need one line the size of the actual bit. Thanks so much for the help!

I will get this shared ASAP!

This is an iinidication that you’re design is setup as a solid line of the shape, which is actually 2 vector lines, instead of a single perimiter. I can show in a short video how to fix… using your project link would make the most sense ![]()

well I was messing around and deleted some points and now I think it shows up in my shared file?

Here is another net I was doing that wouldn’t allow me to use the 1/8 bit. Sorry for all the replys.

yep, It’s shared correctly…

Sometime I talk and click around pretty fast, if you open this in YouTube you can click the gear icon and select 0.75x speed and that isn’t too terribly slow to distort speech a lot. . .

Holy smokes man! That was incredible! I can’t wait to get my next one off the table. Do you have any thoughts about the bit size?

1/8" is used like 80% of the time on my machine ![]()

but you’ll want to get the correct collet if you are using the adapter sleeves because they wear out and then the bit will fall out mid carve… But as far as 1/8" goes, its a winner for the price in my books

The only way I’ve been able to get the design to carve is to choose 1/32. Can I just choose 1/32 and just carve with the 1/8 that but that’s in my router? Or will the new tips you showed me allow me to choose 1/8 bit now?

Yes to this… Once it’s changed from “pocket” to “outside…” and/or “inside the path” then you’d select the bit you will actually use and the toolpath will be set appropriately… this would also explain the initial post of the thickness issue and this fix will make the thickness more accurate ![]()

Should this net take 3 hours to cut? It’s hardwood.

Thats all dependent on the settings youre using for feed and plunge rates and the stepdown (depth per pass).

I would expect to cut it out in under 30 minutes using a 1/8" bit on my machine…

So I chose Hard Maple because that was the choice with the “hardest wood” on my list of options. What would your settings typically be on your machine. If I remember correctly mine were:

30 in/min

depth of 10/min

.03 in. per pass

1/8 upcut bit