Hey guys

Just got my Z-slide upgrade from cnc newbie all put together but am having trouble figuring out what the steps per mm is, I have Phil’s page open that has the converter, but all I have for information on the screw for this thing is from the cnc newbie website. it says that it is 3.175 turns/inch. I’m not a math wiz and have been trying to figure out what that converts to in steps per MM. any help would be greatly appreciated.

Hi there.

I have my machine in mm and I am now calibrating it.

The best value I have found for Z axis is

$102=253.300

I tried it with +- 10mm and 20 with repeatability of about 0.01 - 0.04

Check video for test. I don’t know if this is as good as it gets for me but I can’t get better results with improved repeatability. Will let you know if I find a better value or if someone’s here can tell us what is the precision we should be looking for in terms of decimals. I get mixed results with the same steps…

https://discuss-assets.s3.amazonaws.com/original/3X/d/a/da16d086d167de19009317ee818d83c94123c389.MOV

3.175 turns / inch is 0.315 inches per turn. 0.315 in is 8 mm. 1 turn is 1 rev. 1 rev is 400 steps at 2X microstepping.

So 400 steps / 8 mm = 50 steps/mm

Multiply that out if your microstepping is different.

1 Like

I have an Xcontrller, by how much should I multiply for microstep? By 5?

Wait, what? Where’d you get 5?

Look at your DIP switches. Stock Xcarve is 2X on Z so you multiply by nothing. If you change it to 8X, you multiply by 4. If you go to 4X, you multiply by 2.

sorry to sound dumb but whats microstepping and how do I tell?

Well I am kind of ignorant to the matter and I did my setup by trial and error and i found the best number is:

$102=253.300

So when you said 50!! I went wow! I am way off! But if you multiply by 5 I am at 3.3 over which is close…

Take a look at my video 253.3 is fairly accurate! But why so much higher am than 50!

If I set it at 50… It is way way off! So I am very curious on what am I doing wrong!

I was fiddling around with the $102 number and was around 50 and i was off by about 1-2 MM

Do you have an Xcontroller? Did you set it up per the instructions? Have you changed anything in it for your new Z?

If you answer Yes, Yes, No then you have 2X and you should use 50 as a starting point.

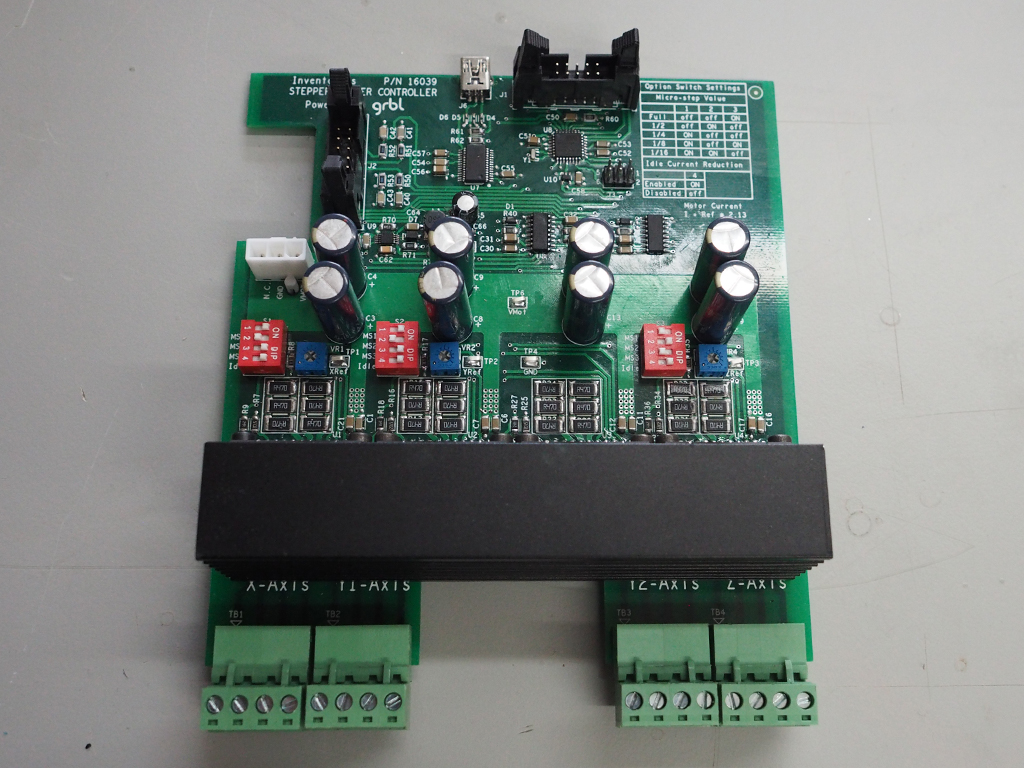

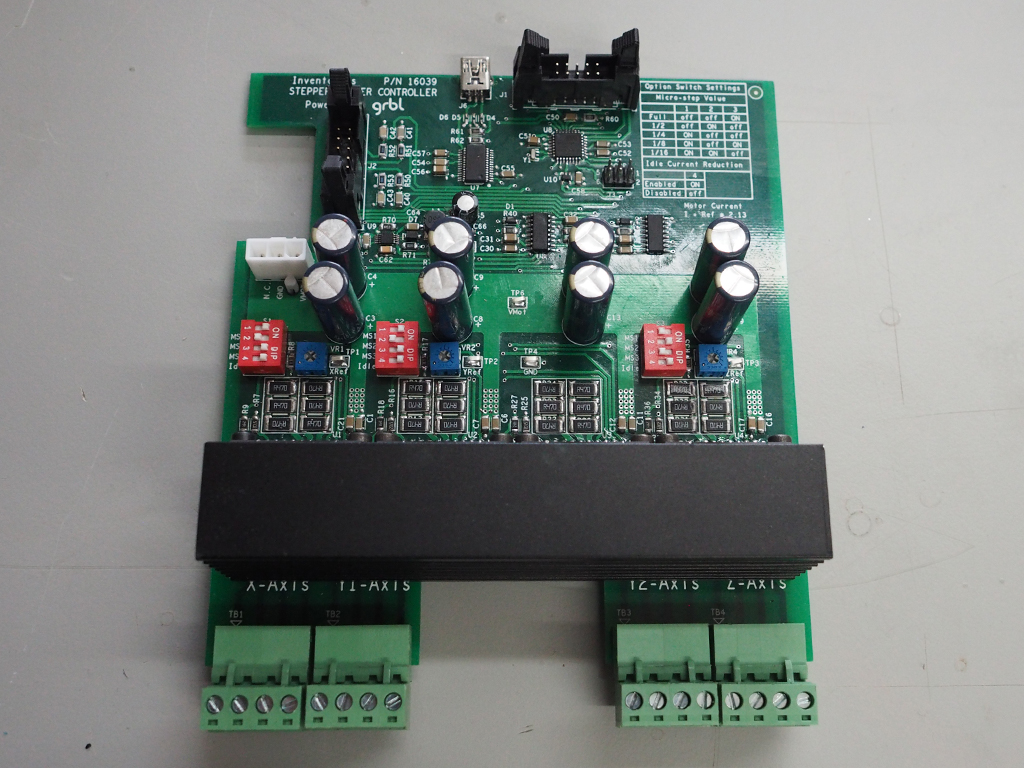

Otherwise, check your DIP switches on the Xcontroller (the settings are silk screened):

For Gshield, its a jumper setting that I can’t find off-hand.

no xcontroller(I wish) I have the Gshield

Do you have the fast screw? what is the turns per inch of your screw?

Scroll down and you see the jumper settings.

Microstepping explanation: Microstepping Myths and Realities | FAULHABER Tutorial

Got mine dialed in, 50 seems to be the sweet spot, thanks guys!

EXAMPLE OF STEP/INCH FOR a standard stepper (200step/inch)

Full step = 3200

1/2 step = 6400

1/4 step = 12800

1/8 step = 25600

Divide those by 25.4 and you get steps/mm.

So 2X would be 251.969 which is close to what you had.

Got it @JustinBusby

I appreciate your enlightenment

Quick question for you:

When testing with a caliper the distance (as seen in the video I attached), some times I get when sending 10-20mm travels about .01 to .05 error… So say, I send 10mm and it travels 10.01 or 10.03… Are those tolerances acceptable or should I keep adjusting the steps to get exact values? Is it even possible?

https://discuss-assets.s3.amazonaws.com/original/3X/d/a/da16d086d167de19009317ee818d83c94123c389.MOV

My z is 50.059 if that helps