Hi

After using and learning with the Xcarve I tought it was the moment to make a choice. I wont bigger and stronger

Or rebuild the xcarve to something bigger…Or building a new one.

I took the choice of a new one. Living in Europe and had the possibility to buy Makerslide MAX 80 x 60mm

Bigger and stronger and the price is affordable.

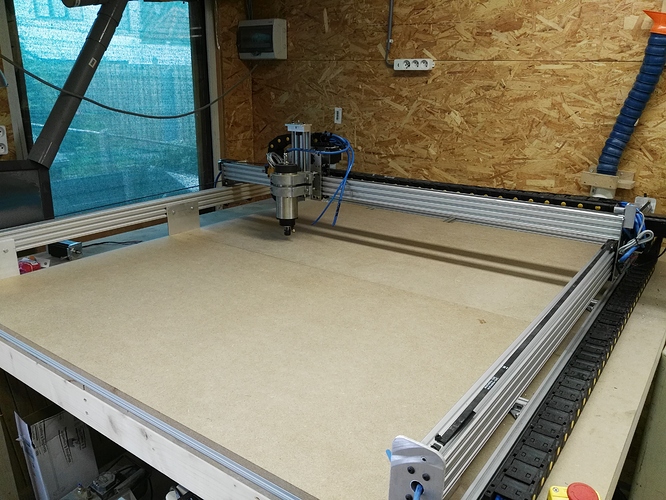

It turns out in a machine x axis 1500mm Y axis 1800mm. Upgrade the z axis ordered a 1.5Kw spindle with VFD and running Mach3 with Gecko540.

All shielded cable Home /limit switches hall effect sensors air assist, bigger cable tracks. Now searching for a waste board that size.

But a photo tells more then thousand words. I m now at the stage for the electronics. That s for the next weekend.

Dont look at the mess in the shop.

I ll keep you informed.

Grtz Koen

.

4 Likes

That looks great.

Very interested to hear how the optical limit switches work for you (assuming those are optical) …

Hi darryl

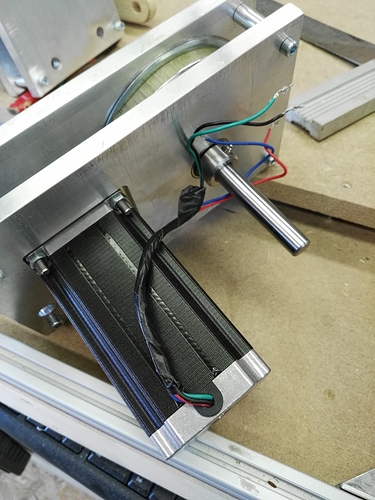

These are not optical, these are magnetic sensors. I read about optical that there are maybe some problems with dust.

Time will tell

Koen

Hell. Yes.

That looks awesome!!

Koen, which magnetic sensors are those? Can you provide a link to the parts you’re using? Thanks!

@DarrylKegg

I just take a look and its NJK-5003C It switch around 10mm. I took a little higher for safety reason. You can also take 5 or 3mm.

I ordered them on aliexpress and its was around 27$ for 5 with magnets. So if it won’t work , not a great lost.

I will give it a try…

Grtz Koen

Cool Build, i’m going to follow your build. for a long time i’m thinking about stiffening/scaling up my xcarve, but those large makerslides open up a lot of options. (im from europe too)

1 Like

Where do you get the Makerslide from , and they can’t ship to the US?

Thanks, I ordered a few of the 10mm version, I’m going to replace my switches once they come in and I can report back…

Hi,

I think they can ship it. But if the price is resonable???

Grtz Koen

Thanks. I’ll check it out.

Daryll,

No problem, normaly this weekend doing the electronics. So maybe on sunday some news. Good or bad, who knows

Grtz Koen

1 Like

Hi,

Its a real buzy time, but I made some progress.

Its all together now. Need to clean up the electronics. And waiting for the shaft coupler for Z axis. Its metric here And was imperial delivered.

But already thinking about a new upgrade. I m not complete happy with the belt system. Im thinking of rack and pinion. Hmmm Maybe later on , first things first.

Koen

2 Likes

MAker some progress again. Didn’t like the belt drive. Machine is running well but too slow for this size.

So next upgrade rack and pinion. base reduction little pulley 20teeth big one 60 will be 1/3

rack module 1pinion 20teeth

i placed some spacers between the wheels to make place for the rack.

with belt driven I could take it to 4.2m/min 6mm bit 3mm passdepth not bad but want stronger and more secure. belt stetch to much on 2meter, 9mm belt

grtz koen

the reduction parts are at the metal shop. maybe back on friday.

2 Likes

I was thinking about this solution the past weeks, i am very curious how it will function.

Ik ben benieuwd hoe het het gaat werken, ga je de as met het grote tandwiel ook nog in een lager plaatsen? en ik ben wel benieuwd wat het uiteindelijk kost om een machine van dit formaat te bouwen. De xcarve zoals die er nu bij staat vind ik niet betrouwbaar genoeg, en de machine is qua bouw ook te licht.

succes met de bouw!

gr Jarno

1 Like

New update

parts are back from the machineshop. because i don’t have an xcarve at the moment I had to go too the machine shop.

alu plate 10mm thick, bearing 28outside 12mm inside, shaft hardened steel 12mm, reduction 1/3, i will shorten the shaft if all at right place.

but now the gantry plates are way to thin and weak. so draw new ones. also make these in 10mm alu.

I ll keep you informed

Koen

,

3 Likes

new Update:

the reduction for the X axis also arrived. Here I took a worm gear because of his size. the machine is standing against a wall And the worm gear is the smallest.

I also made a test for the new gatry plates. i’m gonna double the profile for the X axis.

So the Z is stiffer and has a back up on whole lineair.

Pictures of the z axis support will follow. But also working on the house , so this is the free hours spending in the shop.

Grtz Koen

2 Likes

Hi again,

Did some things today , machine is running!! there is still a lot of work but for now I get rapids of 8 m/min and the pinion is not tensioned.

All the stuff for the Z axis and new gantry is comming on monday. I keep you update.

Koen

1 Like

new day new update

i made a test sample of the carriage running on the x axis.

Its gonna made out off 10 mm alu.

I also double the Xaxis and connect those two together with a T also in alu.

Now I waiting for all the pieces, they are ordered last week and normaly arrives on monday. But vacation is over , so only the weekend :-(.

Maybe you saw already on the photo, the 4rth axis also arrived. he is gonna stand in front , on a sliding floorplate.

So when not in use I take off the tailstock and I can use the whole wasteboard

.Its a 4 claw chuck powered with a nema 34. Max opening 100mm. I wanted a 4 claw for clamping all kind of material. I knew from the early times on the woodlathe. A 3 claw chuck is verry common in metal.

So next update is next weekend.

Grtz Koen

1 Like

Hi Folks,

The aluminium for the gantry plates arrived, nothing special but also the plate for sliding the A axis.

Instalation is for saturday

Koen

1 Like