For anyone interested, here is the the new Z slide I built for the XC. Was really disappointed in the play of the flimsy stock slide and generally angry at the lack of precision whenever making parts. Was generally fine where you might be making a single part where a millimetre tolerance wasn’t an issue. It for anything that was going to be part of an assembly, I’d given up.

I wanted to move the spindle closer to the gantry, reduce some of the leverage advantage from radial force on the Y, and the torque on the X. The was a lot of give in the wheel setup. I think generally the XC Z slide design is pretty poor.

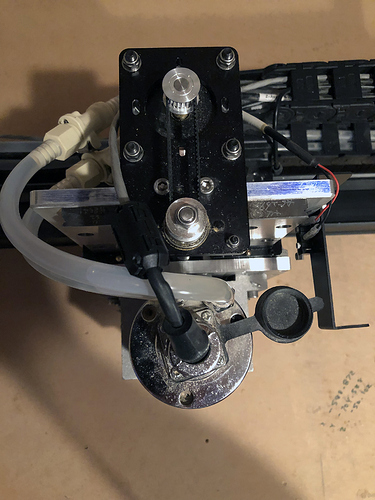

I bought a couple used IKO low profile linear slides off EBAY. Super precise and in good shape. Made a carriage mount and spindle mount plates form 3/8" from 6061 aluminum plate, banged on the existing motor mount and screw gear.

Way stiffer on the X axis. Essentially no play now. Still a little play on the Y, but now just what is in the gantry twist and wheel compression. Maybe 30 percent of what was there with the wheels and makerslide previously.

Next step will be stiffening up the gantry beam. Looks like I could just fit some 1/4” steel flat bar on the front and back faces in the makerslide in the clearance of the carriage. If that doesn’t benefit enough, I’ll just replace the gantry beam with somethign more substantial. May make a new spindle mount and reduce another 5-10mm of spindle extension form the carriage.

All in was probably $100CAD in material and parts. $60 for slides, $20 in aluminum, handful of machine screws. If I were to build again I would design in some additional tramming adjustment. Right now I just have some on the Y, which you cna see with the screws at the bottom of the spindle mount. But X was just a bit of tapping left and right before tightening the mount down.