I have the X-Carve here in my office and we’ve had it running successfully for a week or two. The problem is that (expecially with aluminum) we get resonance and chattering in the machine and my coworkers object to the screeching noises. (6061 aluminum, 0.15mm depth, 4 inches/minute, four flute Ti coated bit).

I know this isn’t enough information to really tell anything but I’m looking for any place to start so I don’t have to tell my engineers they can only play with their toy at night.

If the mill is in a separate room, you can sound proof the room pretty easily with green glue and some additional drywall.

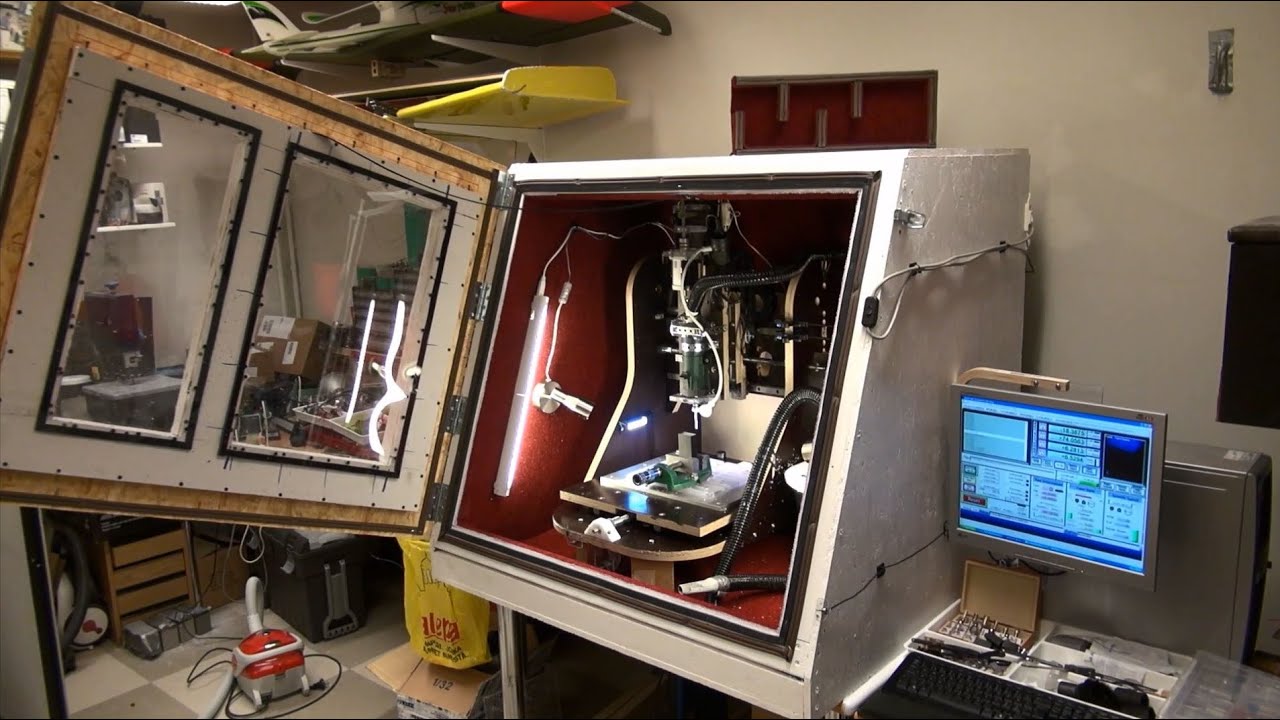

Otherwise you can build a sound enclosure for the mill

Check on YouTube - you’ll have better luck searching “shapeoko” than with “X-Carve” as people have had a lot more time to work with their Shapeokos… https://www.youtube.com/watch?v=uTGKKVcKJm0&ab_channel=tjshape

@LeonGrossman - Anything that will absorb the sound, or dampen/reflect it into different directions will help. The same stuff they do in sound studio booths will work. Eggshell foam, put an enclosure around it, etc… In your case, the high frequencies are more harmful and annoying, which is good because they are generally easier to control or eliminate. Try Googling soundproofing without the reference to CNC machines at all, and you should be able to find some interesting and helpful ideas. Good luck, and be sure to post your findings and experiments so we can all benefit. Also, thanks for giving the details on your aluminum milling. I am always interesting in anyone milling aluminum with a X-Carve/Shapeoko.

BTW, I want to say high pitched screeching can be cured with a faster or more aggressive rate, but I could be remembering wrong. Check out HSM on Youtube.

Thanks everyone for the feedback.

@MakerMark I tried slower rates but not faster. It seems I have some more experimentation to do and an enclosure to build.

Leon

I ran some numbers through Gwizard to see what it has to say about your feeds and speeds.

Using 6061 at .4 HP spindle at 18000 RPM with a .25 4 flute Ti end mill at .006" .15mm DOC .25" WOC at 4 IPM Gwizard advises that chip load is low, may cause rubbing.

When I let Gwizard tell me the recommended feed rate it goes to 99 IPM

These numbers are with a 1" stick out.

Hope this may help.

Dave

I thought the stock spindle was 12k RPM?

You are probably right. Just a second I’ll run the numbers at 12,000.

OK same end mill at 12000 calls for 66 IMP

Dave

I am afraid to go much over 30 imp on most woods. Can the little NEMA motors provide enough torque to move that quickly through the material?

The fun part of CNC is balancing the WOC, DOC, spindle speed and feed rate to your material.

Today I was machining 1/8" styrene sheet. spindle speed was 10345 and feeds went as high as 60 IPM .135" DOC but only .01" WOC.

This was in a Tormach 770 CNC milling machine and I was using all available travel of the machine.

Dave

@LeonGrossman - Another interesting read is here