Hello Mike. Was just wondering if you would be willing to share your Sketchup drawing? I am about to start building a worktable and I realy like the look of yours.

Thanks

Russell

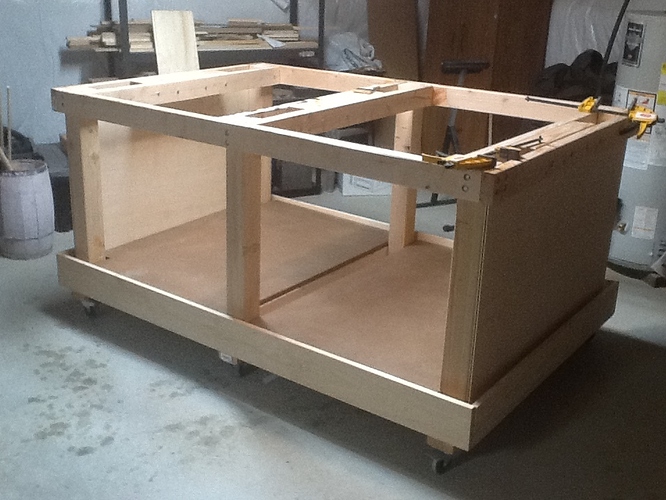

So I am finally getting a chance to work on my workbench for the X carve and have a couple questions for you carpenters. I did two half lap joints to join the legs and the horizontal support. I will be using 3/8" lag bolts to hold them together but I’m not sure if it would be better to use 2 1/2" or 3" bolts. Is it better to leave some meat to the end or get all the thread you can? Here are a couple pictures for reference. Any input would be appreciated. One side will have the controls and cabinets and the other side of the workbench will have 2 heavy duty locking pull out shelves for my miter saw and planer,. Also keep in mind I will have a faceboard that wraps the top that matches the horizontal stained wood.

I used 3 inch lag bolts for almost all of my table, but I didn’t bother with the half lap joinery. As you can see from the photos below.

Very nice Marc

lol I went around to all my local car audio shops and they all gave me the blank stare when I said I had a CNC machine to make custom speaker boxes ![]()

Cool speaker enclosures can be done on a router table and use of templates, the CNC will be a game changer.

thats what I was trying to get them to realize I could make all the parts for that box on my big machine in a quarter of the time

For those of you who have your xcarve on a moveable workbench do locking casters hold the bench in place or is there movement still when operating the xcarve? I have 4 large floor lock feet I can use if movement from the xcarve will cause the workbench to shake or move at all. Trying to figure out if they are needed or if 2 would be sufficient either in the center or opposite corners from each other.

If I had them there feet I’d use em. better to be safe than sorry.

Russell

I agree and I had forgotten the other reason I got them, to level out the table if on an uneven surface.

Now have to decide do I use my left over 3/4" mdf for the lower part or go get 3/4" plywood which would be more resilient to moisture and warping from the weight.

I have 2 inch casters salvaged from a BBQ grill under my machines table , non locking , and have never had the whole shebang ever go anywhere . If it did I think i would need to run it alot harder than it was ever designed for.

I’ve been doing my own XC work station in sketch up and just saw that you did yoursomething in sketch up too. Any way you would be willing to share the file? I’d love to be Abel to come parents the two.

Thanks

Why didn’t I thinknow of a 3 way switch!? Duh!!

Before the first time I used mine I had a ssr hooked up to the 611 and shop vac. But unlike you I bust ran the ssr to a normal duplex outlet for the two. When I wanted to run either one of themails normally I just pull out the plug and plug it into the main power strip.

I am totally going to add a 3way and another lightswitch to my set up!

Thanks for the big duh moment! Lol

Here is the SketchUp I made for when I had the XC. X-Carve Workstation.skp (5.6 MB). When I upgraded my CNC to the GarageWorX 4x4 CNC I designed a slightly different design which still maximized storage and space to store the shop vac and chip separator I use for dust collection. .

Wow that thing looks beefy!

I am planning of putting vac and everything into one stand alone cabinet too. I’ve got a Dyson that the roller foot part was messed up for my DC. Works great and is super quick to empty!

I’ll take a look at your sketch up when I get back to the house. Thanks for that.

Here is my workspace.

I used aluminium profiles with the sizes 30x30mm and 30x60mm.

The Surface is 15mm beech plywood.

The total size is 106cm wide, 76cm deep and 100cm high.

How do you like the Garageworx machine? I went to their page and they look to be reasonably priced. If it’s only around 2000.00 for a complete kit, I’m thinking it may make a nice second machine.

dust collection hose!

It is a really great machine. I was impressed how it was pretty much self squaring as I assembled it. Between the larger and more powerful stepper motors and the steel construction it really increases the capabilities of the machine. Also the acme lead screws is a huge improvement over the belts for the drive system. All in all I am very happy that I upgraded to the GarageworX!