I haven’t yet received my X-Carve but a touch probe is definitely something I am interested in. And I agree that $300. is pretty steep - I see this one as being geared towards the “turn-key solution” crowd that has purchased a CNC Shark or something similar for $3000+, which includes the pre-assembled machine and software.

All that being said, this probe looks interesting as well: Probe-It! Mach3 Wizard – CraftyCNC . The probe itself is $130, and he sells a Mach3 add-on for $30. There seem to be other probes floating around on eBay, etc., for even less.

I agree with @ChrisEllerby, it appears as though any of these probes can be wired to the X-Carve, but the trick is finding, or developing, the software that makes the probe useful. For the ChiliPeppr types I would imagine that some sort of “tracing” macro could be developed to work with the probe. And the software mentioned in the link works with Mach3.

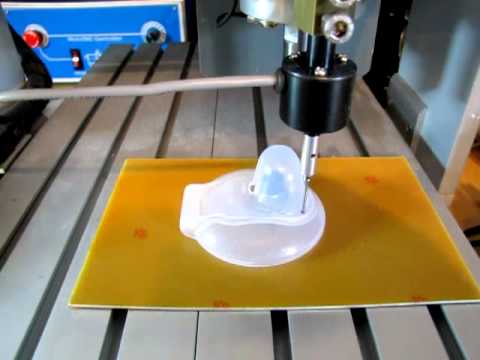

The way I would want it to work is to clamp a finished part to the bed, insert the probe in the spindle, and have the “tracer” software visit each point on the piece, lowering the probe until contact is made, and recording the X,Y,Z coordinate of each point on the surface. This would then be used to calculated a toolpath which could be saved and used to duplicate the piece.

I am guessing the quality of the result would depend on how “sensitive” the probe is (does it make contact strictly in the Z direction, or when contact is made from the side), the “resolution” you used, (how many points are recorded), and the diameter of the cutter you ultimately use to cut the final piece. But I have no real-world experience with any of this.

Another solution to probing might be to take a picture of the piece and, using a grayscale image, use some software to convert it to a 3D toolpath. Or, maybe a 3D scanner …

. I would love to be able to have this sensor from the beginning, but having to wait is worth it . . .

. I would love to be able to have this sensor from the beginning, but having to wait is worth it . . .