When I drilled the mounting holes for the bed and used DIN912 screws, I knew I was blocking half of the slots. The resulting pattern of slots was blocked-free-free-blocked. I therefore designed my wasteboard layout so that the exposed slots would be the free ones.

But the OCD inside me was telling me this doesn’t feel right. What if I want to use multiple configurations on the bed? What’s the point of having a T slot bed and be locked into a single configuration? If I wanted a single configuration I could get T slots between strips of wasteboard. What if I want to get Adam’s kick-■■■ low profile self-centering vise whose mount holes are spaced at 60mm and fit a free-blocked-free-blocked pattern?

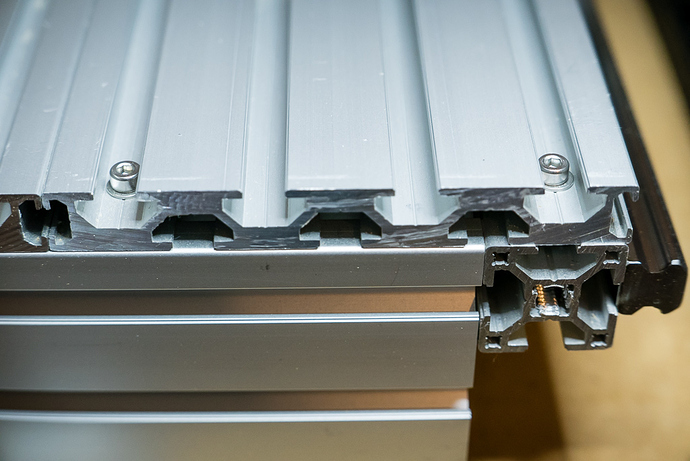

The internet is a wonderful place. After estimating all clearances on what I was hoping was a perpendicular shot (by measuring on my screen with a toy plane ruler - don’t tell anyone) I found a countersink bit that could fit the narrow slot profile. Here is the moment of truth.

It worked like a charm. I was able to switch to DIN7991… and to a free-free-free-free pattern ![]()

And then (life is short) I got Adam’s kick-■■■ low profile self-centering vise.