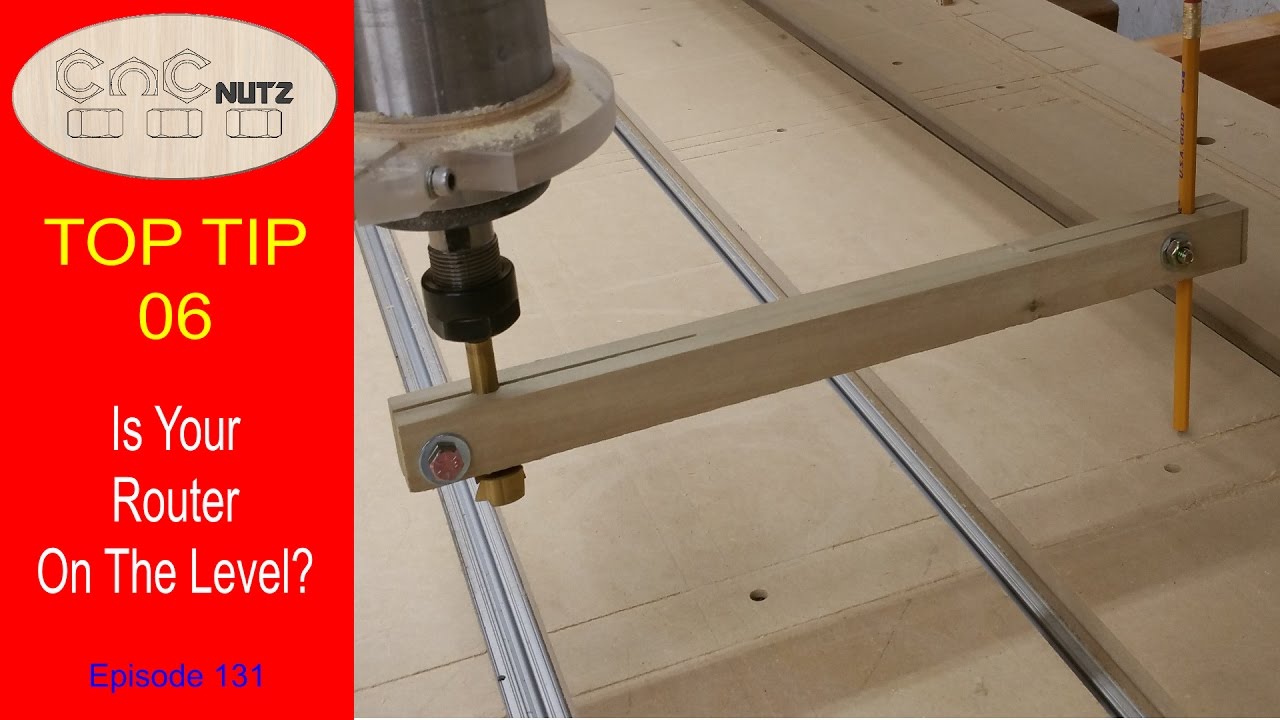

Hi. As you can see from the picture, my X-Carriage is not square to the wasteboard. The rail, however, is square.

Can I adjust the v wheels or do I need new ones. I may have misaligned them after an earlier mistake and the spindle tried digging for oil!

Alternatively, can I get round this by adjusting the rail?

Thanks

I would start with a deep cleaning first.

Yep. Thanks. I’ve just finished quite a lot of surface flattening. The crud hasn’t knocked the whole machine out.

Get your buddy to give you a hand, loosen up the Maker slide and tweak it back beyond square to compensate for weight of the

“Z” assembly and you should be good to go.

Most likely the v wheels eccentric nuts are loose, which will allow for this forward tilt due to the center of gravity being up front where the router is…

HOWEVER the angle you’re measuring doesn’t actually matter, the goal is tram aka the spindle being perpendicular plane to the x,y plane of movement. Granted, achieving tram MAY require adjusting that angle, it’s also possible that adjusting the angle of the Z assembly by shimming the back of the Z assembly (the 4 bolts that hold the Z to the bracket your square is touching) and leave the gantry alone, even with that angle.

A simple upgrade to help with improving the rigidity of that gantry is to change out those top 4 vwheel screws out to a pair of Longer single bolts for each side (so those top 2 vwheels shown in your photo will change from 2 separate screws to a longer screw) this reduces deflection across those 2 shorter screws.

Have you used a tramming gauge in the spindle itself like the one in this thumbnail?

Design doesn’t really consider a proper bearing edge for that spindle weight side load from the torque. Aside from a different fundamental design, probably would have done better having another set of adjustable wheels on the horizontal to pick up some of that load and provide some minor tramming adjustment.

I replaced the delrin wheels with steel to get rid of the play from wheel compression. If you keep your maker slide clean, seems to not inflict wear on the rails.

And then shim the spindle plate out to square. All you can really do with it is reduce the play and tram out the spindle. I don’t recall that there was any useful adjustment in rotating the gantry makerslide. And I think it would just twist back when making Y cuts away from the spindle side, unloading the problem points. Basic rigidity problem.

Did this happen after the deep-dive or after your what you did?

If the rail is square, but the gantry is not, I would check that the v-wheels have not been shifted on the bearings themselves. You could also check the bolts to see if they are bent. That is, unless the v-wheels are just not tightened correctly…

{:0)

Brandon Parker

Thanks for all your replies and suggestions. Sorry I haven’t got back sooner, but I’ve been on other things.

This weekend, I shimmed the Z rail and it seemes to have done the trick.

Kev