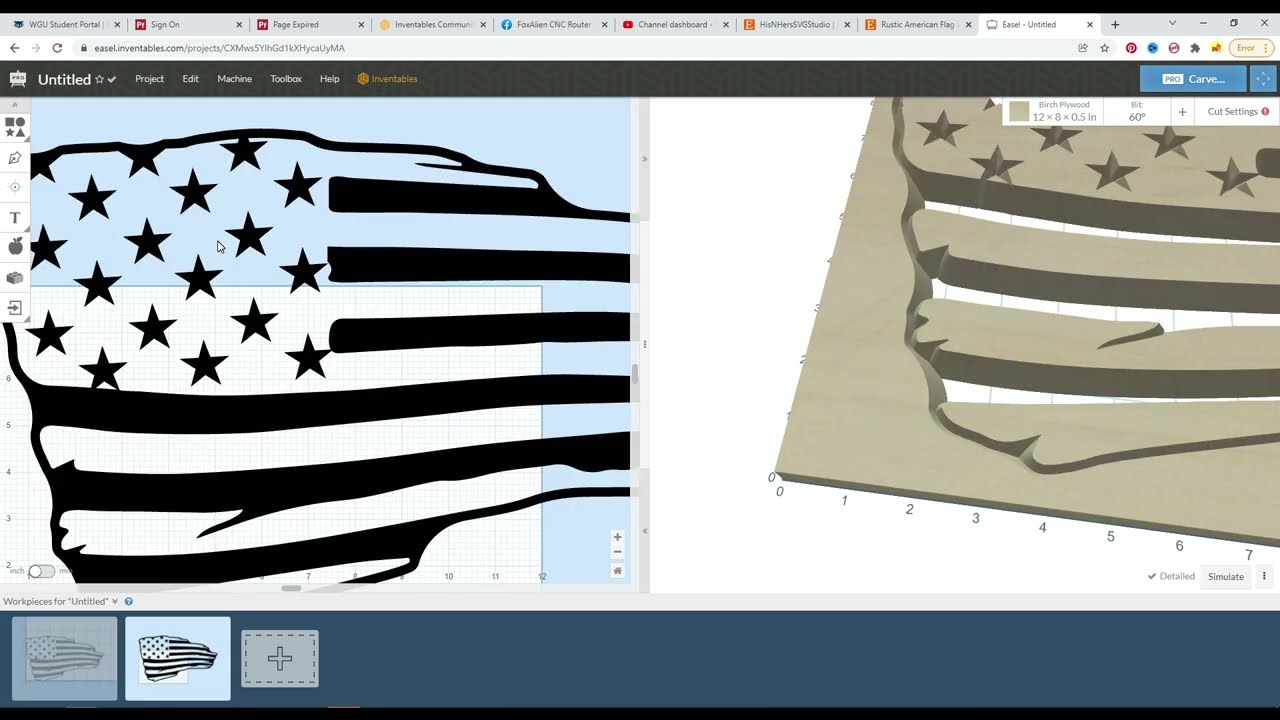

I am trying to invert a project. Whereas the outside is cut away and a raised design is left. Currently the design is black (the cut away area according to the program) and the uncut area is white. How do I change these to the cut area is white and uncut area is black?

Thanks for the information. It was a bit too fast for me and had to stop and backtrack several times… No offense but this video was definitely done by someone who has worked with the program for an extended time. I had a hard time finding all the buttons/icons used when the instructor just flew through the steps. I think I found what I needed. Thanks again.

I think I have my design where I want to run a sample/prototype. What is my next step to getting it to the router?

Oh the video is also listed as “private” and not released publicly, i made it specifically for one person a while back to help with one issue. That said, if you click the gears ![]() one could change the play speed to like 75% without distorting the words too much… anyway, glad you got it figured out

one could change the play speed to like 75% without distorting the words too much… anyway, glad you got it figured out ![]()

As far as sending the program, have you done the machine setup and the carve button at the top right is green indicating the cnc is connected and ready to go?

My CNC is in the other room separated from the computer. At this time I was planning on using the MicroSD card that came with the CNC controler. Or possibly a thumb drive that I can plug into the back of the CNC.

Which model cnc?

Fox Alien / Masuter. Sorry I am not sure of the exact model. But the cut area is about 15" x 15" x 2".

The black (original masuter) or orange one (masuter pro)

Btw, i help admin their Facebook group, with 13k members … lots of other foxalien machine owners over there who always help each other out ![]()

Oh and i happen to own both the masuter and masuter pro ![]()

The Black one. And I sent a “join group” request

I have the programs on the SD card. Inserted it into the Offline Controller. Played with it a bit until I got the CNC to “trace” the design. By “trace” I mean it went trough the x and y axis measurements to see if it would fit. But when I press send on the controller it will go left and right but the spindle did not activate the bit to spin. What did I do wrong?

When I put my bits in, do I put them in as far as they will go or should I try to measure the length of the bit below the collet?

Not up in the collet to the point that they bottom out, and not so far in that the collet clamps onto the cutter portion. But there’s no need to make them all have the same stick-out length either, this is accounted for when the Z zero is set for each bit…

This topic was automatically closed 90 days after the last reply. New replies are no longer allowed.