If I bolted a piece of wood or mdf down to the corner, overlapping my home (or g28) position with the intent of carving a square out of it beyond the top and right side edges to form a bump stop, would I want to carve as an outline on the inside edge to make the bumpstop edges flush with the starting x,y coordinates? Or would I want to carve out on path, or possibly even just keep the square filled instead of carving it as an outline?

Hi Phil,

Sorry to keep bugging you but I have a question about your bump stop. Does it matter what size bit you use to cut the bump stop? Since you use the g28.1 command to set it, would the location be different for different bits? Getting late, maybe I am overthinking this?

Goodnight. Lol.

I may be wrong, and we will let @PhilJohnson or anyone else who wants to chime in, correct me if I am, however.

I wouldn’t think that the size of the bit would have much of a difference when making your “bump-stop” or positioning reference jig… and here is my reasoning behind this. When you use use the g28 or g30 commands you are setting a reference point to a place on the machine where you want the center of the bit to locate. Since your reference point for each work piece is most often the lower left corner of the material to be carved, this is where you want the center of your endmil/v-bit to reference. The center of rotation (or center of the bit) is always the same regardless of the bit size…

so to answer question 1, I don’t think it matters what size bit you use to make your bump-stop.

question 2. the center of rotation for every bit is the same (not taking account for any possible run-out or misalignment of the bit when chucking it into the collet) regardless of bit size and it is this center point of rotation, or point of the bit that should be referenced to your material.

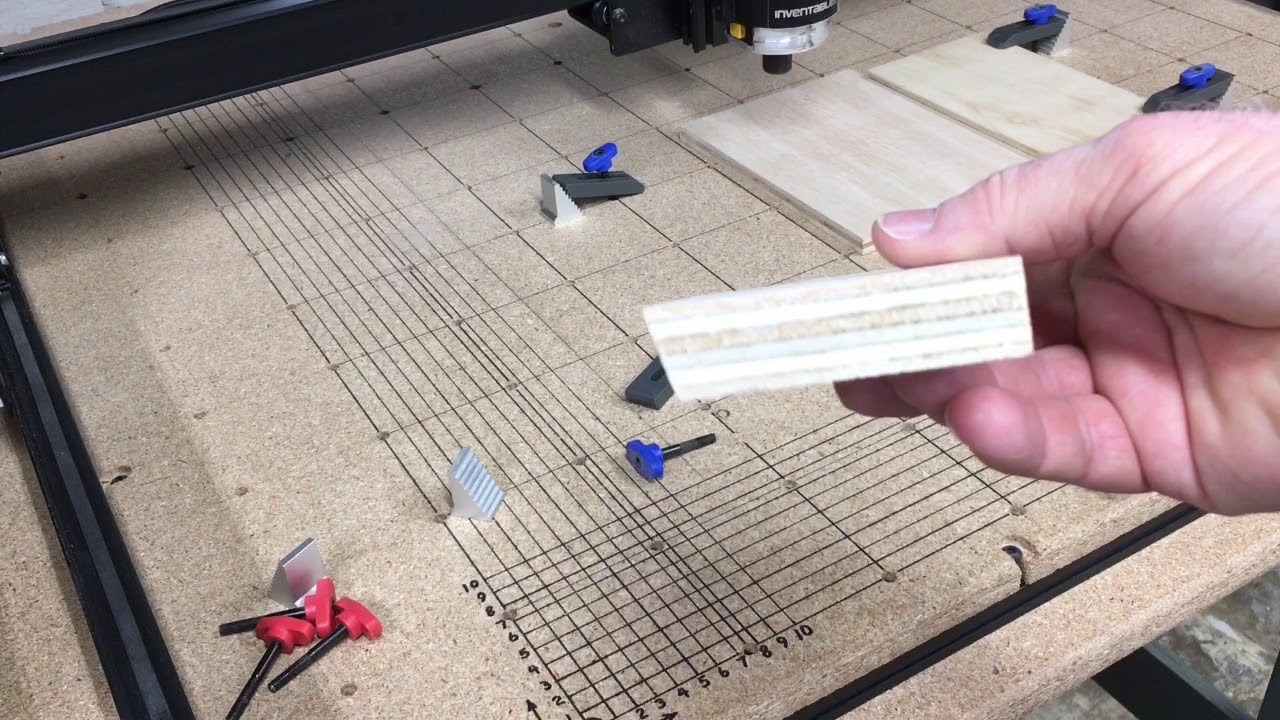

There are several different approaches to Bump Stops. I use two strips of 1/8" white melamine (tempered hardboard) screwed to the waste board. I cut three elongated screw holes in each to allow adjustment. I first attach the Y side and align it to the Y path. The X side is then aligned either with the X path or more quickly by just using a framing square. Then set G28 at the inside corner. I do have about a 3/8" circle cut out at the corner for clearance. (Same idea of Phil’s dog bone). Drawing below to better explain.

Why I like this - 1. Readily adjustable for fine tuning. 2. Low profile which allows easier clamping of thin stock and allows better access for the 3 axis Triquetra touch plate. 3. I can remove the X guide for longer work pieces but still have the Y guide in place for use. This also allows a quick and accurate reinstall using a square. 4. I can write on it with a pencil or dry erase pen and it is easily erased.