Using my 3018, material is 3 mm think, set cut depth to 3 mm, plunge rate to .5 mm and Easel keeps cutting to 6mm deep. Good thing I have a waste board. This is driving me crazy. What am i missing?

Thanks for a reply.

do manual Z commands operate correctly?

in other words if you command 10mm of Z movement (up or down) is it actually moving 10mm or something different? (I’m guessing its moving more)

Well, I’ll check but I don’t think that the case, because I cutting out an ornament but there is also a carve in the center which is at 1.55 mm depth which looks correct. If you are correct, I would I correct that problem?

thanks

If your z movement does not match what is commanded you need to calibrate the axis movement, this is stored in the grbl settings as $102

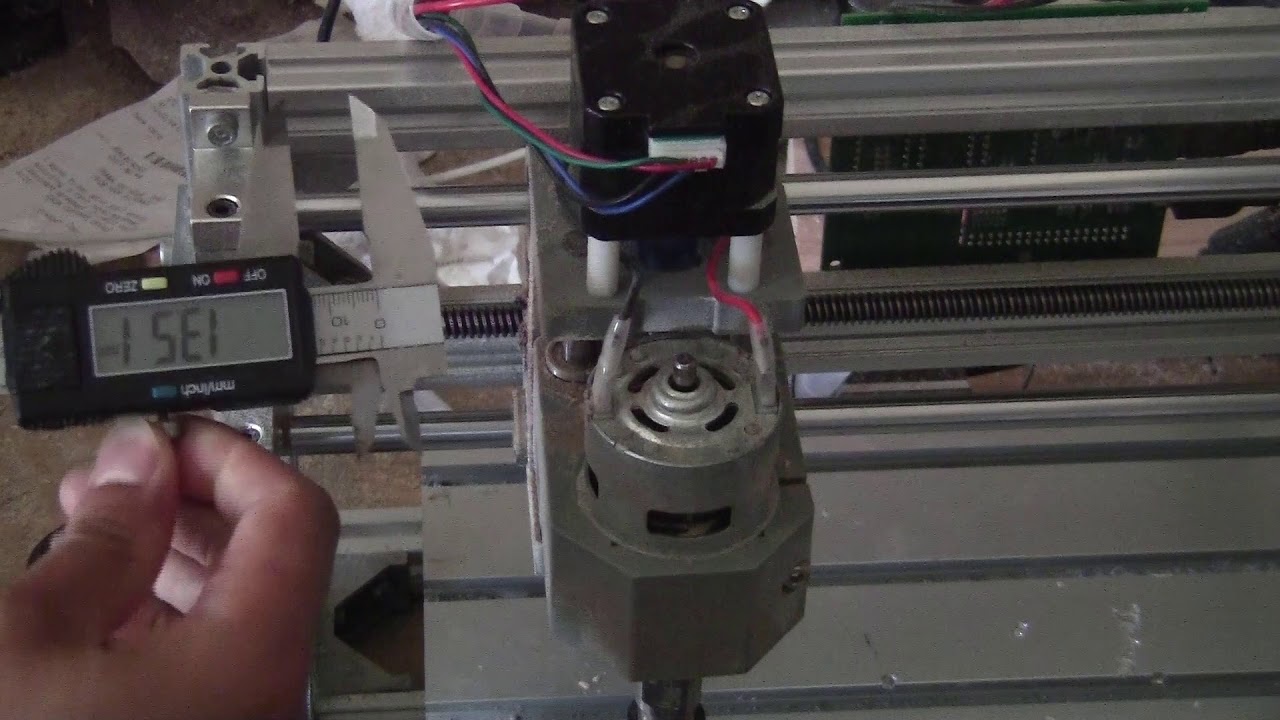

There are a bunch of videos on 3018 axis movement calibration on YouTube, most are a little difficult to follow, but you can actually watch some on the xcarve and the process is basically the same, (command a specific movement & measure the movement, place into fraction, include the existing value of $102 and cross multiply to determine the corrected value of $102)

A heads up though, if you go through machine setup and select one of the xcarve photos, it will change your $102 value to that machines default value. This is actually an issue that many new cnc owners go through, picking the wrong one and having the value changed is quite common.

IF the movement is accurate then the next question is, is the 1.5mm accurately cut center area the area that was used to set z zero? (maybe the top wood has a low spot right here, although 2mm variance is a LOT on that small cnc)

Thanks for the reply. I’ll have to digest it. I’m new to this and have not worked with changing codes directly. But first, I’ll export to UGS for the cut as I have not had problems with carves done from there as opposed to Easel direct carves. I thought this was so simple, I’d let Easel carve. I have has the same result with three different pieces of wood, so I doubt that is a problem.

I worked through some of the YouTube vids, made some Gcode changes and I have Z properly calibrated now. Thanks for you help.

Awesome Tom! Glad you’re all sorted

Well I thought I had this all sorted out, but I don’t. I’ve jogged my machine in all directions and measured the results with caliper and it moves correctly when jogged. Yet, it still insists on cutting at twice the Z depth of the project. So frustrating. I wish I had someone to sit here and show me what I’m missing. This is why I bought an inexpensive machine in the first place. I figured if I got frustrated by software I could just abandon the tool and not be out much. I’m almost there… Any more suggestions?

When you experience the depth being off, are you setting z zero with a probe or paper?

Also, how far away from the place that z zero was set was the actual carve?

Could it be that the workpiece has a low spot where the z zero is being set?

Another rather common issue is the router set too low in the clamp and this can cause the z axis to top out when the carve is started and the initial move up to the origin safety height.

.

To verify depth you can make 2 pockets of varying depths (pockets that overlap.eaxh other are good here too) and see if its only the initial plunge that is too deep, or if the variance is multiplied

Like let’s say the first carve is set to 0.25" deep, and the second to 0.5" and the first one actually measures ar 0.35 and the 2nd one is 0.6"… both are 0.1" extra (this would indicate that the z zero is simply set wrong…or .maybe using a low point on the board…or the z axis topped out.) Each of these root causes can result in this same excessive depth issue…

Thanks for the reply. I doubt it is a problem with the board or table being unlevel as it has happened consistently on a number of pieces. It is often twice as deep as requested. I will experiment with overlapping shapes in different areas of the piece as suggested.

The other problem that I have is the limited number of bits available in Easel Free. I have to use “other” and put in a width but this does not account for the shape of the bit. I’ve tried to carve text in various fonts that I have created in Inkscape, converted to a path, exported as svg and imported to Easel. They show up as expected, but I have to set the depth of cut deeper than I want to get them to show up completely in the 3D preview.

What your explaining (Double depth) leads me to believe that z calibration is still off… (this is the $102 setting i had prior mentioned)

HOWEVER with the 3018 a common issue is that the z axis is hitting the top and since it’s losing steps from hitting the top it will plunge deeper than intended…

You can go to machine>general settings and reduce the origin safety height and the safety height and then it won’t try to lift as high and this should stop it from maxing out the lift ![]()

if you’re using a v bit without paying for pro, then that workaround really is not the best solution, takes forever to carve and doesn’t result in anywhere near the right toolpath for a vbit.

Can you share your gcode for a file that cuts too deep?

To address previous question, the spindle never tops out or bottoms out on the Z axis. Bed is dead level. I am presently running a test carve with 4 sets of overlapping squares in various locations. Cutting path only as that will be enough to measure depth. The video is helpful. I am not familiar with Gcode beyond $$ and $102=something. I can’t quite see the format of the commands he used to drive the specific distance. Guess I need to find a Gcode tutorial. Standby for test results. (BTW, I’m an old retired guy with this new hobby).

I deleted those projects but here is one where the cut depth was 3.3 mm, plunge rate 0.2 mm, but it stabbed the bit right at the start and bogged the machine, so I aborted. Angel2.nc (911.1 KB)

Test results all over the map. I started to carve 1 in square pockets but that was going to take 3 hours and it stabbed the bit right off the bat. Changed to cut on path, one of each set to depth of 3 mm, the other depth 1.5 mm, plunge rate 2.2 mm. I hope you can view the pic I uploaded with the results.

There’s a lot to break down here…

I agree, I put these into a spread sheet and they do not follow any consistent math, like it’s not off by multiples (usually the case when $102 is off) OR by additions/subtractions (this is usually the case when Z zero is off) … or any combination of these indicating both issues at the same time…

Do you mean Depth Per Pass of 2.2mm? This could be part of the issue, I have a few cnc’s including a 3018 and I usually run it at 0.3-0.5mm depth per pass, (the 0.5 is mainly MDF).

And with a plunge Rate of 100mm/min and Feed of 700mm/min…

In that Angel file everything looks normal, I see a depth per pass of 0.2mm, plunge of 100mm/min and a feed of 150mm/min

So maybe the line of “2.2mm plunge” was supposed to say 0.2mm?

At this point, with the inconsistent depths, I’m kinda making a few guesses based on other common 3018 issues:

- Is the Coupler (usually blue) that holds the stepper motor shaft to the lead screw tight? (no loose set screws)

- Is $1 set to 255? (setting it to =255 will make the steppers hold position after the carve is over), this will prevent any gravity related issues causing the Z to drop back down, I say this because the Z might be moving around after the carve

- Oh one more common mistake is the method for using the collets if this model uses the ER11 collet: it’s actually quite common for people to put the collet into the spindle and then the nut on, sliding the bit in last, but the correct method is to put the collet into the nut (it snaps into place) and then put that into the housing and then the bit in and tighten down the rest of the way.

Yes, plunge rate as supposed to be 0.2 mm. ( I have problems with the “2” key on my keyboard.)

I’ll check the collett situation. I’ve never taken it apart, I always just change the bit.

Thanks for continuing to help the needy…

This topic was automatically closed 90 days after the last reply. New replies are no longer allowed.