Last year, my girlfriend bought me my very own x-carve. (Yes, she’s amazing like that). Took about 2-3 weeks to get to know what I’m doing and where the bit goes. Soon after, I made her a nifty sign. After I made the sign, what did she do? She went and sold it. And that’s how the story goes. Right now we do about 50 custom signs a month as well as about 50 “pre-designed” signs. All these signs isn’t leaving much room for the x-carve to be used as it was intended, as a toy.

So my question is this, have you ever gotten burnt out and started to dislike the “toys” that you’ve purchased?

1 Like

Age old tale, friend. This happens to many people when using their passion to make money. One thing is to raise prices or do higher value jobs and use that extra money to clear up time for playing around / creativity. Hard place to be, for sure.

That sort of happened to me… except that now I’ve decided that my goal is eventually to crank it up to 11, and make my home shop my full-time job. I’m not quite there yet, I still need more steady jobs, but in the long term, I want to be able to make my shop my full income. It’s a lot of work, but I like working for myself, and being responsible for my own future, instead of at the whim of some pinheaded bureaucrat somewhere higher up in the company.

Well, she saw my post and we talked about it. Her solution: Get another x-carve!

2 Likes

Both my girlfriend and I work full time jobs as well as our 2 home business that have grown into 3 etsy shops. We are now in 5 local stores as well. Granted it’s not all wood signs, but about 60% comes out of my wood shop. I love making stuff and the stores give me reasons to make random things. It’s just the signs that are burning me out. That fun of design and such is gone.

I like where your head is at!

And please don’t take this post the wrong way. I am very thankful that Im fortunate enough to be in this predicament.

Dang, sounds like you guys are CRAZY busy! I’m pushing the line myself with only one small business!

For repeat builds, I’ve found that good fixturing / tooling makes all the difference for me. Turns a drag into kind of a breeze.

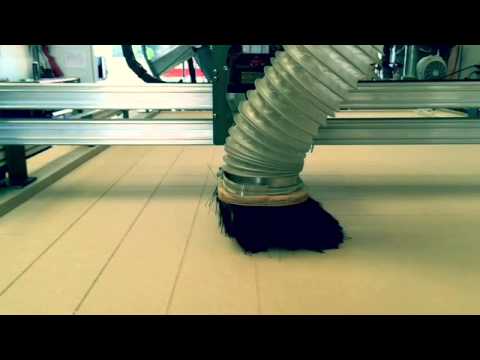

The X-Carve is a great machine, but for true production work getting a larger machine that cuts faster so you can layout lots of blanks in fixtures. Then you just set the machine up and start the job. about 80% of the tedium goes away and you can concentrate on doing the things that are more fun, like design and optimization. It sounds like you could pay off a new machine pretty quickly, plus you can deduct the machine price from store sales instead of paying taxes! So really it is like having the IRS buy your new machine!

Then you can use your X-Carve for the fun projects you want to do, or even just convert the X-Carve to a laser engraver and add that dimension to your business.

We are looking into larger machines to do larger signs. I hadn’t thought of the batching aspect of it. That might be a good selling point for a nice 4x8 machine!

1 Like

We are crazy busy. I’ve found ways to quickly change out blanks, but the problem lies when you offer 3 sizes of one style and then two completely different style signs it comes down to more of the order to do things to change out the “jigs”

With a 4x8 bed you would have room to keep all (or most of) your jigs in place. Not having to constantly change out jigs and fixtures makes life so much easier.

1 Like

I just have no clue where to start when looking at those.

Do you want to build a big machine from parts (like the X-Carve) or purchase a pre-assembled machine?

I’d assume buy a pre-assembled machine?

Shopbot and Laguna are two of the best know CNC routers for production work. But they are very good but are going to be expensive

Or you can get a machine like the Gryphon if you don’t want to spend nearly as much.

I’d be tempted to go to quick-change jigs. Drill in a set of pins to the X-Carve top, and make matching base-boards for your jigs using the same program. Then build your jigs on top of the base boards, and use toggle clamps to lock the jig down to the waste board. Set up right, it’d take seconds to change jigs. You could even keep the same G28 home if you were careful with your X and Y stop sizing on the jigs, since they would all index to the same spot on the machine.

I stalled out on a project for a friend which caused me to put aside a lot of projects that I would have rather been working on. I eventually got fed up with it and just stopped working all together for a couple months. Now I’m trying to re-motivate myself to finish it and move on.

Basically, it started as a simple trophy, which turned into 10 simple trophies, which turned into 10 trophies with 20 parts each (not so simple anymore)… you can kinda see where that’s going. We redesigned the trophy several times and I’ve probably cut at least a couple hundred dollars in wood making them. My only motivation right now is finishing this project so I can do other stuff.

1 Like

The worst project fatigue I ever had was when I “volunteered” to make a commemorative box for my friends daughter when she graduated. He kept redesigning it not knowing how much more difficult each new idea was to implement. Plus he had a really tight deadline that could not be missed. I got to the point where I just wanted to call and tell him the machine was broke and he should find someone else to do it.

What started off as a fun project for a friend turned into a death march and in the end neither he or I was happy with the result but he knew better than to say another word about it. But I felt so much happier the day after I gave it to him and my involvement with it was done.

1 Like

I became burnt out with the xcarve cause I was having so many problems with it because the waste board was starting to shift for some reason it dipped down in the middle cause of the humidity. My xcarve is still down cause I ran out of money trying to upgrade it. My original idea was a toy also then trying to see what I can make to sell. Then I saw the acrylic signs and started selling those I have another cnc machine that hasn’t failed yet. And I’m trying to get the money up to finish all the upgrades on my xcarve

1 Like