I have spent the last couple of days trying to figure out why my maker’s slide does not stay square to the machine upon shut down. I have insured that the machine is square. I even made a couple of the spacers for setting the slide evenly at the front of the machine. Once I power up the Controller, all is well until I shut down. At that point, the left end of the Maker’s slide ( as you face the machine) moves rearward about a 1/4" inch. when I restart the Controller, the slide does not go back to the correct position. Any thoughts as to why this is happening. I believe it is a recent occurrence. I found it when prepping a new auxiliary spoil board and the grid carve was all askew.

Wire harness to tight and pulling it back, belts possibly are a little loose.

thanks for the insights, Ken. The wire harness is located with no pull back on the gantry carriage and the belts and set to a 3lb/inch as measured on a suitcase scale. I have readjusted the V wheels and that seems to help a bit. I did some additional adjustments after slackening the belts and then retightening them. It seems to have solved most of my dilemma. The X pathway is now pretty perpendicular to the Y axis and the X axis is also well defined. So, the issue was really the gantry carriage torquing on the rails. I’ll run some test cuts tomorrow and see where that leads but for today, I feel pretty confident that the problem is resolved.

This can occur if the Gantry crossmember was not cut squarely from the factory, which was an issue some years ago, i think it was a batch in the 2017-2018 time frame that were not cut perfectly square.

The fix is to either re-cut all of the X parts including the frame parts to remove that slight amount, or to shim it whilst performing the test measurements until the motion is repetitively square. I hate to say it, but the X-Carve design does keep the costs low, unfortunately at the expense of rigidity in some areas, like using thinner side brackets and the makerslide which is thin walled and pretty weak against twisting.

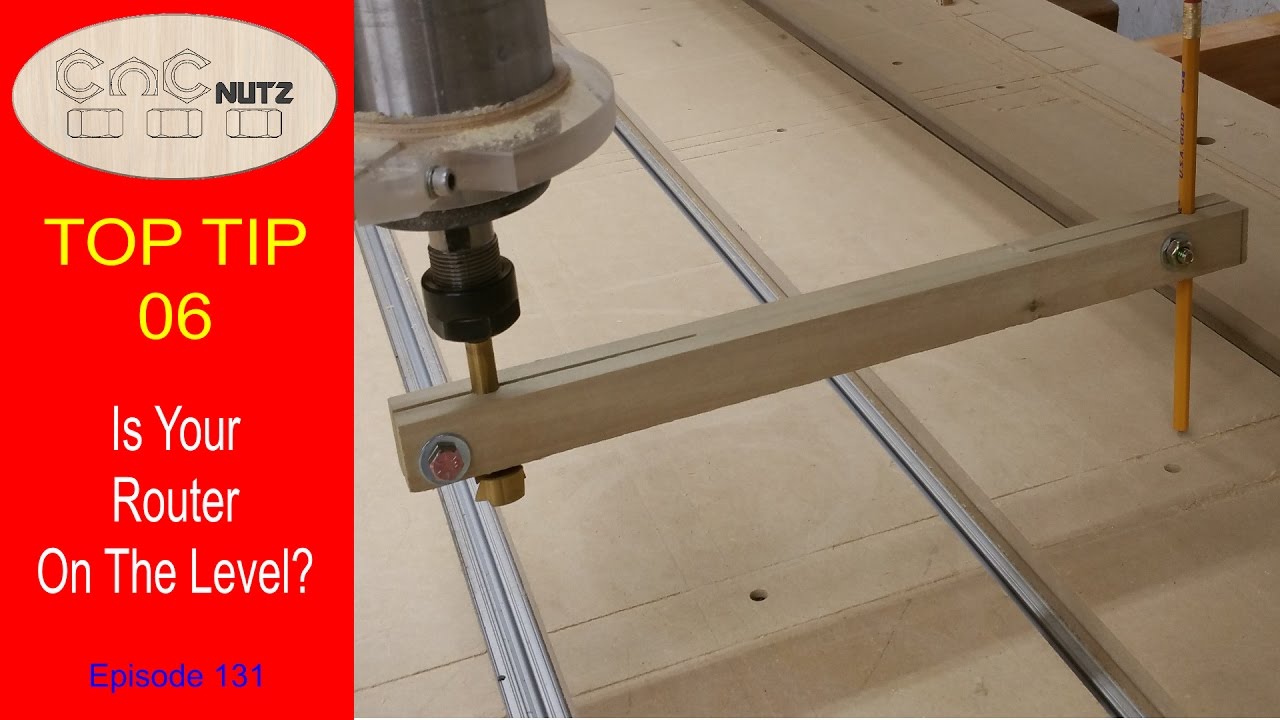

Perform this motion test is a better method of proving square than measuring the frame itself:

Seth, thank you. After screwing around with this machine for 2.5 days, I have finally gotten it squared away and, thank you for the video. It’s the best I’ve seen and in comparing that technique to the ones I used prior, I know the machine is square; spot on. Now, that said, I’m still messing around to insure that the spindle is perpendicular to the base and is square on the maker’s slide.

Here’s the style tool and the method I prefer… Note this MUST be performed to a freshly SURFACED (using the CNC itself) surface. Like by surfacing the wasteboard then setting tram. This is OFTEN done wrong, and the X-Carve Manual aids in the incorrect process a LOT (I wish they’d change that part of the manual if you can’t tell). . . without further ado

Yeah it’s a different CNC so the method of adjustments are different, but the tool, the and the rest of the process is what I’m trying to relay…