I’m very new to this software; however;

i need a quick intuitive way to avoid clamp locations on my workpiece.

if it already exists its buried and should be a very quick “in your face” button to mark and avoid clamps on the work surface while in easel pro.

thank would make my life much better. thank you.

A vacuum table, double sided tape or masking tape and super glue.

Spiral cam Clamps bolted to the spoilboard, tighten the bolts so the cams do not vibrate lose.

Long wedges a personal fave.

Dog holes with plastic pipe dogs. Some of us use PVC, I use pex.

too expensive and slow. need a software solution

hate to break it to you. There is none.

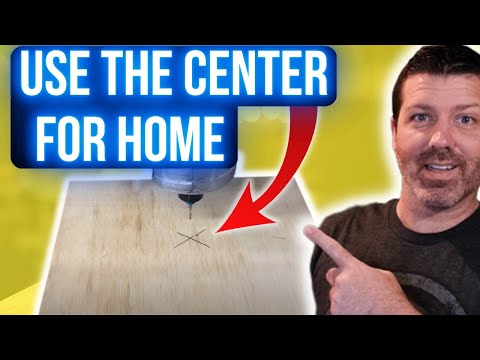

One Method would be to use Center as the Origin. If the cnc never moves to the perimeter of the workpiece then it won’t hit any clamps.

Another method would be to use the Origin Safety Height setting to increase the Safety height of the First and Last moves of the cnc which would help to avoid clamps.

I know of nothing faster than long wedges if .you are doing production work.

If you want a software solution, you will have to learn g_code and plot each clamp in the g_code as a no go part of your design, which would take you a very long time for each new setup.

20 years ago +/- I designed an optical sensor for detecting broken milling bits, maybe you could put a colored lamp on each clamp and program in a sensor.

This is a good idea- and it would be nice if it was built into the software but it’s not. Why not measure your clearances (for instance, if you’re using the dust boot you’ve probably already noticed you need more clearance on the right side than the left to avoid the threaded rod clamps) and then plot a shape (probably a rectangle) with 0 depth, and plant that sucker right where your clamp is. Then copy, paste, repeat.

This is really just for a visual cue to see if the layout will work. I know what you mean. I’ve hit clamps multiple times and their must be a better way. 2-sided tape is not practical or safe for certian sizes and materials. I never use it.

My go-to is to use a biscuit joiner to cut pockets into the side of my work piece corresponding to the wasteboard holddowns. Then the oak clips and machine screws sit below the plane of the carve all around.

With 4x4 sheets where theres no wasteboard visible, I usually get away with just 1 or 2 threaded rod clamps. The weight of the sheet is usually enough to hold in place.

Other than that, you just have to hover over the pause button and clench your butt every time you’re near the clamp like the rest of us!

great solution thank you

This topic was automatically closed 90 days after the last reply. New replies are no longer allowed.