I’m getting ridges on the cut surface using my X-carve pro. For example doing a through cut of 3/4" MDF with a straight 1/8” fluted bit, the machine will take 6 passes to get through the material, I can distinctly see lines from each of those cuts as if they are seemingly cutting slightly off from one another.

What would cause this and what sort of adjustment is needed to fix it?

1 Like

sounds like your z axis needs to be trammed. Doesn’t sound like it is square to the material/waste board. You will still likely see machine lines on the edge of the material, but you shouldn’t be having actual ridges

3 Likes

Thanks! Sorry for the newbie question but how do I tram the z axis on an X carve pro?

1 Like

@SethCNC do you have a good vid already made on this?

1 Like

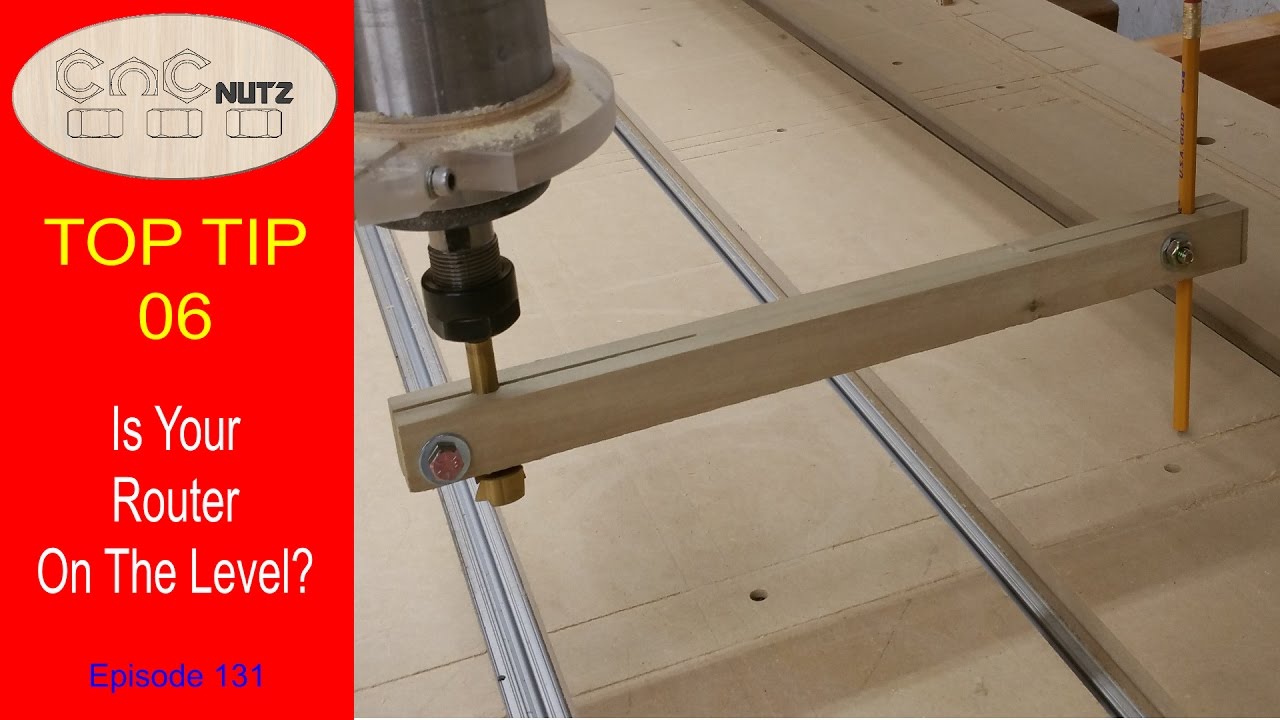

I dont have one that ive made but i think Peter covers the general process very well in this video, but it uses a different model, so the actual adjustment locations are different on an xcarve, but all of the videos that actually do use carves leave out many of the key elements peter talks about /shows here. .

Thanks! Here’s a picture of the issue. Does this look like tramming would fix it?

You should see everything off the same amount and the same direction if it’s a tram issue. So if the spindle isn’t at a 90 degree to your spoil board you should have a consistent bevel to your project. If it doesn’t have a consistent “slope” then I would think it’s a workpiece holding issue.

Stupid simple tools (SST) makes a great tramming tool that comes in super handy. You could also run a profile pass to cleanup the edges if you are in a time crunch, but definitely fix the issue sooner than later.

I’ve asked this question directly to Inventables support and they seemed to indicate that the issue could be the gantry is not seated appropriately on the Y axis. Try checking that the guide is firmly seated on all four linear guide blocks on both Y and Y2.