Hello,

I purchased the 1000mm x 1000mm about a week ago and am currently waiting on the X-controller. In the meantime, I’ve been researching and designing different solutions for a soundproof enclosure. I share a condo with a roommate and obviously neighbors, so I need to cut down the noise and vibrations as much as possible. I’ll also be relocating within the next six months so I was hoping to find a design that doesn’t weigh as much as a cow and can be dismantled with relative ease.

It seems like the only effective solution to the noise problem is the “room within a room” design. Thus far I’ve come across two ideas that might serve my purpose, but the end product for each design was achieved in different ways. So I’m curious what other people have to say about this fact.

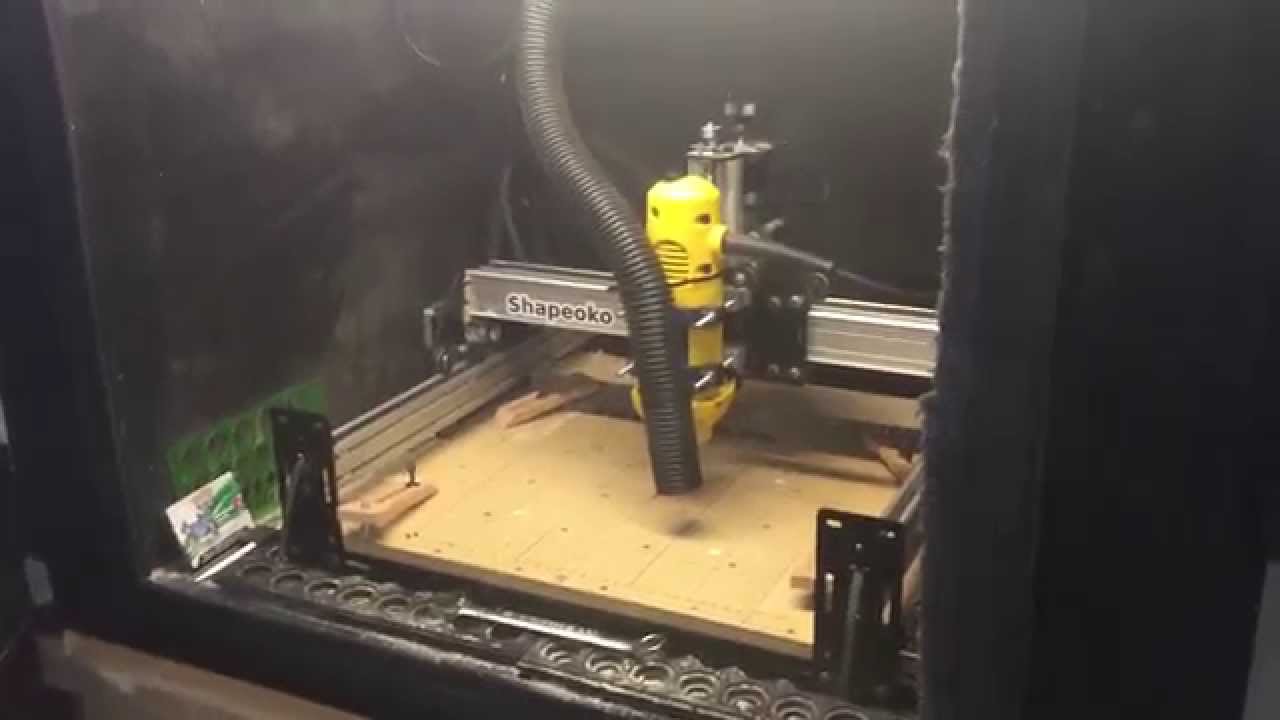

My initial idea was based around @tjshape’s build on the Shapeoko forum.

It’s essentially a massive 2x4 frame skinned internally/externally with 1/2" soundboard and 1/4" drywall. It uses Denim R13 insulation for a dead space filler and green glue sealant/compound to stifle any leaks. I’m sure a lot of people have already seen @tjshape’s proof of concept video, but I’m going to share it again because I am truly astonished by how well it works.

The obvious downside to this, especially for a 1000mm machine is that the damn thing ends up being the size of a dumpster. I’m scared to even guesstimate how much it’s going to weigh. Unfortunately, due to space restraints, I would have to mount the door hinges on the X-axis instead of the Z-axis. So I’m not 100% certain that I’ll even be able to lift it. Lastly, due to all of the sealant/compound, I’m not sure that it could be disassembled and relocated without destroying its structural integrity. But this could certainly be due to design flaws on my part.

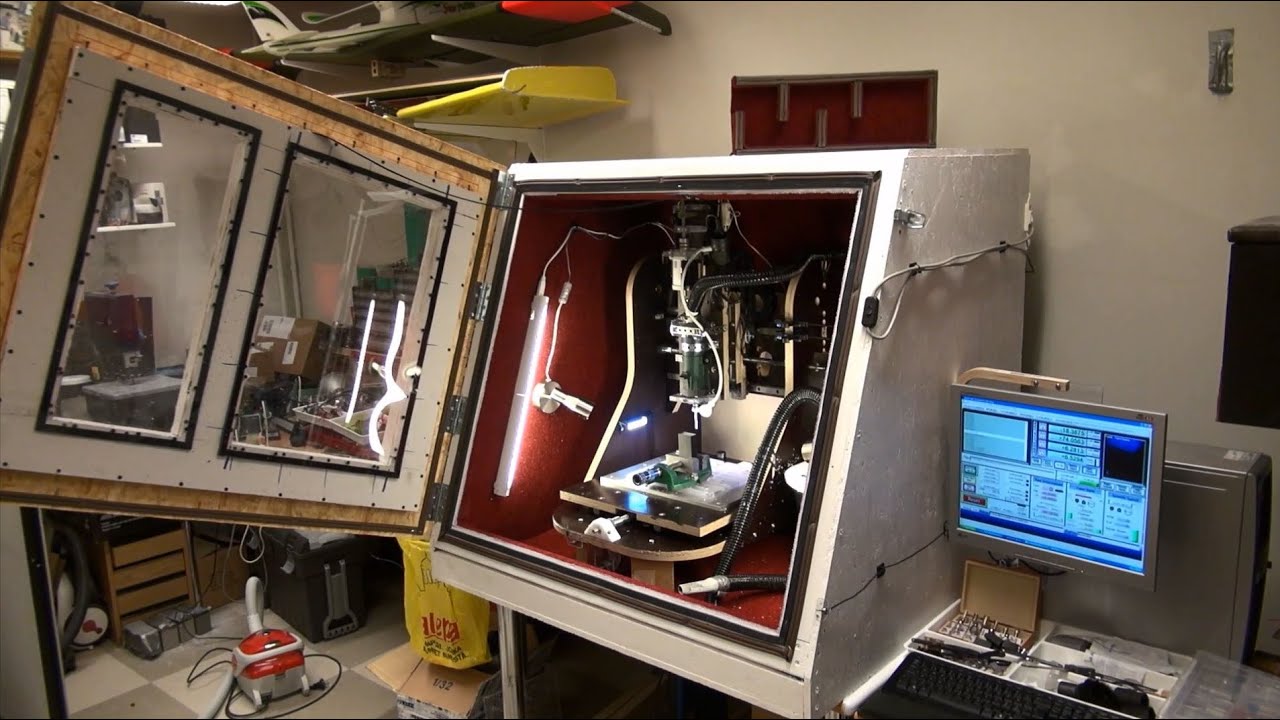

I also came across a different enclosure by Protocorner on Youtube that operates using the same principle but at a fraction of the price/weight.

His design is basically just a 1/2" plywood outer shell, “Mineral Wull insulation” (not sure what that is), and a 1/2" drywall inner shell covered in carpet with a baffle box over the intake. I doubt it’s anywhere near as efficient as @tjshape’s design but it nonetheless cut down the noise significantly on his video. And best of all… it’s modular.

Does anyone here have experience with an enclosure utilizing this type of construction? It would be so much easier to build and transport, which makes me question whether or not it is too good to be true.

I also have some general questions for anyone kind enough to answer.

-

I am planning to leave about 3" of clearance between all four sides of the X-Carve and the inner skin of the enclosure. Is that enough room for the drag chains as well as anything else that I might be forgetting about?

-

How do you make adjustments to the X-carve after it’s been placed in the enclosure, especially the rear? Any tricks for this?

-

How do you get the X-carve into the enclosure without throwing off any adjustments that you made prior? Any tricks for this?

-

Im planning to leave about 2’ between the internal top skin of the enclosure and the tallest point of the gantry. Is that enough space to facilitate full X and Y travel without the dust collection hose (mounted dead-center) getting tangled up on the gantry?

-

Dust collectors - Any opinions on the following?

Grizzly G1163P - 1 HP, 537 CFM Light Duty Dust Collector - Polar Bear Series

POWERTEC DC5370 Wall Dust Collector with 2.5 Micron Filter Bag -

This question is entirely relative but I’m curious nonetheless. Would I be better off using a cheap Shopvac in a sound enclosure until I have enough space to install a large dust collection system. Has anyone here purchased a 1 HP system and experienced buyer’s remorse?

-

I’ve also purchased a JTECH 3.8W laser with a cheap Chinese vacuum pump. My plan is to vent the exhaust directly through a homemade enclosure in a window. Is it legal to do that? Or do I need to build a filtration system?

If you’ve gotten this far… thank you for taking the time to read all of this. I’m extremely gun-shy concerning what to do at this point. So any advice, or even outright criticism would be deeply appreciated!

Thanks again.