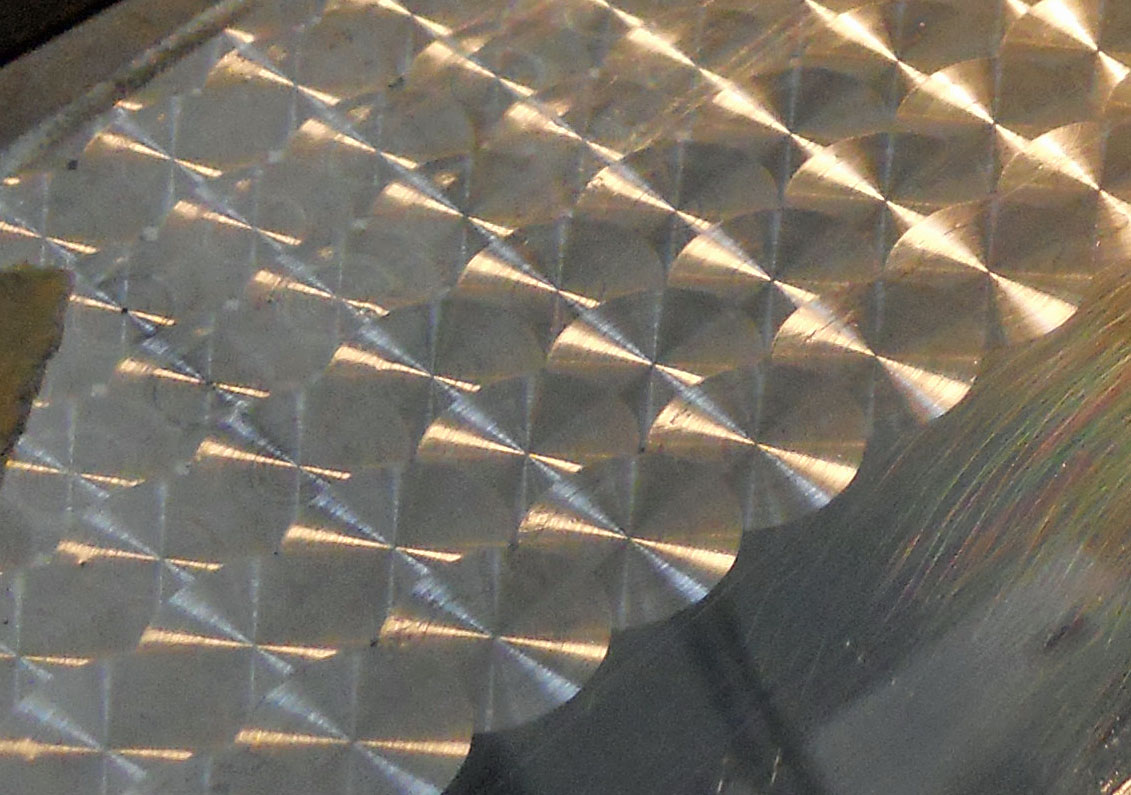

I want to texture a small sheet of aluminum with a swirl pattern. I’ve done it before manually but it is very tedious and is a perfect job for my x-carve. Problem is I’m not very familiar with writing G-code. What I need to do is take on old router bit and glue a small circle of leather on the tip, about 10mm in diameter. I then mount the piece of aluminum in the x-carve and coat it with oil and a very fine abrasive. Now comes the hard part. I need to write code that starts at x0, y0 and lower z until it just touches the surface, raise the bit, move 7mm on the y axis, lower and touch, raise, move 7mm on y and repeat until it reaches the end of the piece. Now I need it to move to y0 and x=7mm, and repeat the whole previous process for the next line, move 7mm more on the x axis and so on. I don’t think it would be very hard but I’m not versed in G-code at all. The finished product has a very nice swirled pattern. Can anyone help me out?

sounds like you need an array of shallow drill holes with a 7mm spacing

so do you have a picture of the pattern that you are after?

are you talking about like how you swirl the aluminum with a sanding disc?

When I did it manually on a drill press, there was no heat build up. You just need to touch the surface.

Thanks Phil. I’ll try this.

This was produced in Vectric Aspire, a 3 x 3 array, not tested

T1M6

G17

G21

G0 Z20.0000

G0 X0.0000 Y0.0000 S12000 M3

G0 X0.0000 Y0.0000 Z6.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X7.0000 Y0.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X14.0000 Y0.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X0.0000 Y7.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X7.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X14.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X0.0000 Y14.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X7.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 X14.0000

G1 Z-0.1000 F1524.0

G0 Z6.0000

G0 Z20.0000

G0 X0.0000 Y0.0000

M30

Please post pics of the result. This will be interesting to see.

Figure out what you want to do for a single swirl, then use Easel’s replicator app to duplicate it however many times you like. Maybe load some steel wool into the end of a dowel and pretend to do a bunch of .001" deep holes. You can get more scratch time if you lower your plunge rate, but may want to lower your safety height so it doesn’t take forever to move between scratches…

I thin kthis would be super easy to accomplish in Fusion 360 or easel using a scotch brite pad mounted to a arbor in the router although it is concerning that the arbor would be moving at a minimum 8,000rpm on my machine and 16,000 on a x-carve 611 router

just import spirals into easel and tell it to cut on path and let her rip

Instead of using a bit, I use a piece of leather attached to the end of a old bit. Then coat the metal with oil and a powdered abrasive. Then run the program to just touch the surface of the metal. By using a 10mm round piece of leather and only moving the bit 7mm, the swirl patterns overlap by 30%. It is a very cool effect.

this is what I meant by arbor I used these all the time when I was a mechanic and it will swirl effect aluminum no problem

I have to look at the rating they might handle up to 20,000 rpm I used them on my die grinders all the time

These would work on a larger surface and I’ve seen it done on fire engines etc. But the piece I want to texture is only 8" (203.2mm) by 4" (101.6mm), so these are to large. I only want the swirls to be 10mm in diameter.

I have seen this effect.

I never knew how they did that.

Take a 1/4" wood dowel and drill a 1/8" hole about 1/4" deep in the end. Get a little steel wool and epoxy it in the hole, with a dense tuft about the diameter of the desired swirl sticking out. Chuck it up in your 1/4" collet, use Easel to pretend you’re drilling a hole .001" larger than whatever bit you tell it you’re using, and experiment with speed and Z-height (aka pressure) to get the swirl you want. Once you’ve got that, use the Replicator app and git’r’done.

You may also be able to just scatter some fine sand on the aluminum and use the end of a 10mm wood dowel (modified to fit your collet) to swirl it in. Probably want to throw a diverter of some kind on your spindle if it’s got airflow that goes down toward the tip though, it’s no good to blow the sand away.

Sounds like a perfect YouTube video to me.

lol I have already started I hope to have the video out some time tomorrow!!

will be here

Custom spiral tool? perhaps just a prototype!!

By the sounds of the OP’s description he is referring to an old metal finishing technique called “engine turning” which would look pretty much like this when complete.

yeah that is what I am going to replicate on the cnc machine thats my idea behind what the op is after