I’ve been looking for instructions to tram the XCP, but I can’t find any. I want to make sure I’m adjusting the correct screws. Can anyone help me out?

Thanks for responding to this, Dave. My question is specific to tramming the X-Carve Pro spindle, though.

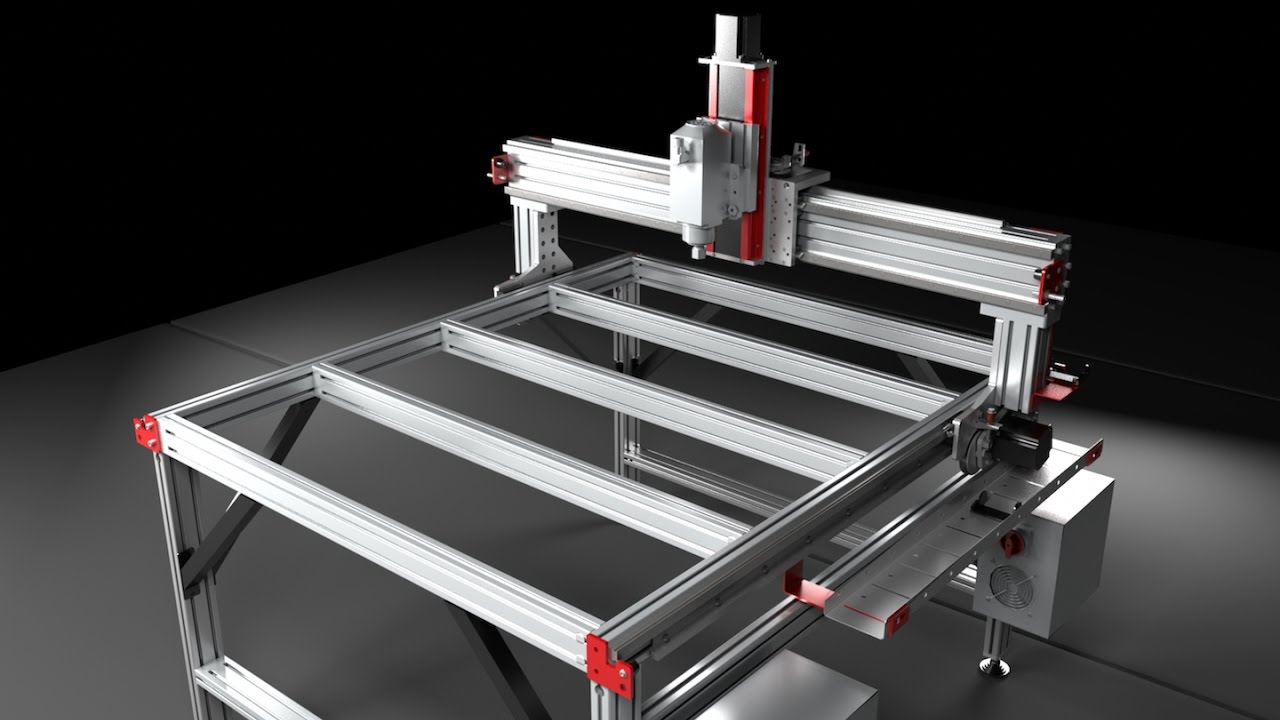

My bad. Attention to detail… Not sure if this helps but I recently bought this and have yet to see how it works:

https://smile.amazon.com/dp/B084GDD7WN?psc=1&ref=ppx_yo2ov_dt_b_product_details

I’ve got that in my cart as well. Just haven’t pulled the trigger. ![]()

For now, I’m using the board method. Just don’t know where to make the adjustments.

I loosened the screws mounting the X-Axis to the Y-Carriage on both ends. The x-axis and spindle were balanced enough that it didn’t feel unsafe doing the process by myself, but I think it would be faster if you had a spare set of hands.

I built my tramming tool using a scrap piece of wood, a 0.25" drill bit, and a shorty No.2 pencil. Adjusted until I could draw a perfect circle and then tightened the Y-Carriage Screws.

Sounds precarious! ![]()

Adam,

This is a great video on tramming put out by AvidCNC. I haven’t taken the shroud off of the XCP VFD to see if any adjustment is available but this is by far the simplest approach I’ve seen. You could probably even use the files from AvidCNC to run the gcode on the XCP. I’m going to try and run these test cuts sometime this week and see what my results are. I’ll report back. Below is the video link as well as the instructional link from AvidCNC. Hopefully the XCP has some type of adjustment if the results aren’t ideal.

Thanks for the share. I look forward to hearing your results!

Wow, that really was a useful video!

Square test went great. I’m not sure what I was expecting but after I ran the gcode to drill the four holes they measured exactly the same when I measured diagonally, just like in the video. I’ll probably run the tramming test in the next couple of days then report back.

Ran the tramming gcode in both directions and got great results. Side to side had a minuscule ridge on the step over. Front to back was dead flat. The only thing I could think of to tilt the x axis front or back to get the side to side more flat is to put some tin foil or a small shim under the side legs where it meets the y axis slide. Ideally you’d shim the spindle but I’m not too keen on doing that. However, I’m not planning on doing either at the moment though as I think it’s barely noticeable.

Here’s my [low quality] tramming video of the XCP. I’m aware that not everything I said was accurate. I don’t think well on camera. Maybe I’ll take this down and put a better one up. ![]()

Adam,

I think the video is just fine. I haven’t taken the cover off to see if there was any adjustability so I’m glad to see there is from the video. With that said was there quite a bit of adjustability? It looks as though it wasn’t too bad out of tram (if that’s the right terminology). I’d love to see an eccentric nut on the left to right adjustment like the avid machines have. I’m not sure if that’s an easy add-on. Nonetheless, thanks for the input!

Jonathan

There was enough play to make me pretty confident that it was intended for this reason.

Awesome. You know I’d like to see Inventables put out a video on this. I think it’s important enough to warrant it. @Zach_Kaplan

Thanks again Adam!

Please an email to help@ to discuss. I think this should be escalated to Giovanna.

Thanks everyone.

Thanks Zach, I submitted a support ticket on this matter for discussion. Thanks again for the reply!

Hello @AdamCook1 @Bricbasher

Thanks for bringing this to our attention.

Our hardware team clarified and reiterated the X-Carve Pro goes through several rigorous checks in each step of the build before it passes to the next station. Every surface in the x and z axis is machined with very tight tolerances to ensure perpendicularity and our assembly line uses several fixtures to achieve this.

In other words, our manufacturing process involves machine surfacing on every plate that comes into contact with each other to make it as easy as possible to assemble the X-Carve Pro. The X-Carve Pro assembly does not require additional fine-tuning as you may have had to do with X-Carve 1000mm or other cnc machines.

This is one of the benefits of purchasing X-Carve Pro. Our design is meant to involve the least amount of intervention.

While tramming the spindle is something that could be done, Inventables does not recommend these adjustments as it could undo the precision achieved during the manufacturing process.

If you have any issues with your carves or questions about X-Carve Pro, please reach out to our Customer Success team and work with our Technical Support agents.

You can call us or reach us via email at help@inventables.com. This is the best way to work through issues, receive the most accurate information and a timely response as Customer Success does not monitor the Community Forum.

We strongly believe the Community Forum should be reserved for peer-to-peer collaboration.

Our Customer Success team works very hard to ensure we respond within 1 business day and if we need additional support, we will reach out to the respective teams.

Giovanna,

Thanks for the reply. It’s good to know that the XCP is designed with such tight tolerances. I haven’t noticed any problems with anything being off as of yet. I understand that other machines such as the original x-carve and the avid cnc machines don’t come with a preassembled gantry/spindle so I understand why they would need tramming. If the need for tramming ever does arise for whatever reason, I will reach out to tech support.

Thanks again,

Jonathan