Hey guys Figured since this is my latest big project that I would share the progress here and also hopefully get some advice/feedback from you guys! I’ve had this build on my mind for a few months now. I actually came up with all the sketches when I was at the hospital for 8 days with my newborn daughter. Anyways, I plan on building a Camera Slider for my YouTube channel than I am working on, where I build knives. Allot of the work I do on a knife is tedious and boring so making time lapses would be great! Along with the really cool footage you can get using them. Anyways on to the build

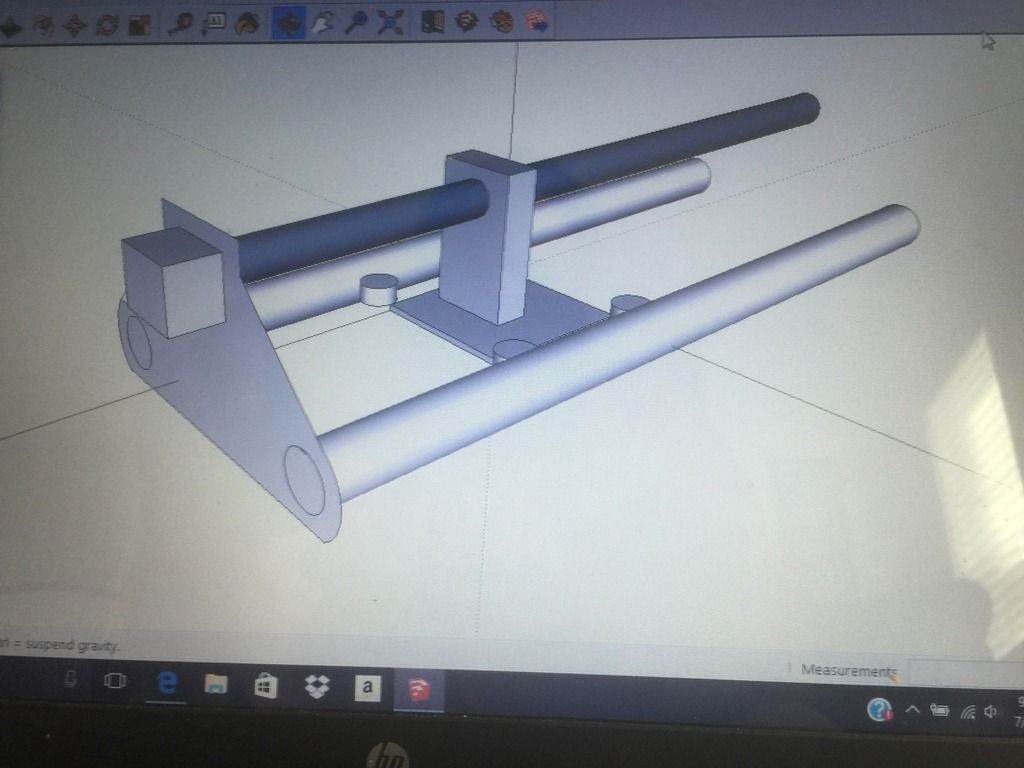

I am still on the fence if I want to make this first one motorized or not. I have some ideas on how to implement the motor system but still have lots of brainstorming to do. I took my sketches hit up a friends house that had autocad and began the design. Luckily he was able to teach me a few things and I came up with something use able. I am going for lightweight and compact, so I bought 2 1000mm carbon fiber tubes! These things are super ridgid and very light! I’ve worked with carbon fiber before and always loved the look of it. I designed the two end plates in easel but I think I will modify them to reduce the weight of them and make them look a little neater. I am doing all my test pieces in MDF. I am thinking of doing the endpieces in aluminium but I am unsure if the xcarve can cut such thick material. The middle plate, that you see in the picture I plan on making carbon fiber, most likely 2-3mm thick. And the slider I plan to also make out of carbon fiber. I also picked up these grooved wheels from ebay that seem to fit the pipe fairly decent.

Problems so far:

- The two endplates I made out of MDF where supposed to be a snug fit but are fairly loose. I am not sure If I should try to get a better fit or if I should implement a hole with a threaded knob that could push down to tighten them, the nice thing is, is that the endcaps I bought prevent the ends from being able to fall off, they can only slide forwards.

To do list:

Next up I plan on designing the slider platform where the ball mount and vwheels will mount to, I also have to mount the bottom plate, but I am petrified of putting holes in these carbon fiber tubes they where about 50$ each… I may see if I can find a copper tube that is the same od and id and use that first.

Questions I have:

What materials do you recommend I use for the endplates is aluminium an option? Or do I go with some sort of plastic?

UPDATE

Alright So upon working on the top slider, I found a potential flaw to my original design, Originally I was planning on having the wheels on the inside of the bars to keep the slider as slim as possible and figured it would look better mounted this way, having hidden wheels, Anyways the bars aren’t mounted far enough apart, so it leaves a just less than a 1/4" gap between the wheels. This isn’t much of an issue but I plan to implement a motorized pulley, this doesn’t leave much space for the belting and any belt clamps etc… Alternatively I could have the belt run along the top however I feel like that would just look ugly. So my next option is to mount the wheels on the outside of the rails. So to fix all of this I can either make the rails farther apart Making the entire thing wider. Or I can design the slider to have the wheels go on the outside of the rails leaving tons of room in the middle for the belts and anything else that has to be implemented. This only makes the slider wider. Thanks to the wheels being grooved I can slide the slider onto the rails and it will be able to stay in place, allowing me to also have the rail upside down to get even lower shots.

Here are some pictures for reference. Let me know what you guys think.

ANOTHER UPDATE

Well spent a few hours doing some measurements and adjusting the file to cut out the top slider. Had to cut it out twice as My dust boot got caught and I lost a whole ton of steps. Anyways for now I just kept the same design as the bottom plate and will adjust it later on when I get the ball head mount and other things sorted out. I was pretty worried about the fitment but my measurements seem to have been accurate, It slides right on, and to my surprise it stays on the bars even while upright with ought the bottom plate installed. As mentioned earlier I am petrified of drilling any holes in this carbon fiber so I opted to wait until I have everything else finished. I attached the vwheels (They are not V-Wheels but that’s what I am going to call them) to the slider using M8 Bolts. For the actual design I wanted to tap some threads in the bottom so that there isn’t any bolts or holes showing on top. This is an option If I opt for Aluminium but if I go with carbon fiber I will have to go with bolts since the carbon fiber will only be 2-3mm thick. If I do use bolts I plan on going with some black bolts like you see on the x carve. Anyways still lots more work to do, but in theory I have a working camera slider!

Next up:

Next I am going to go back to the end pieces and redesign them. I got to find a method to keep the end caps from slipping down and moving, so far My idea is to thread a hole on each side and have a threaded knob to push down onto the bar to lock them in place (hope you know what I mean) I also plan on buying a cheap ball head mount so that I can mount my camera and do more testing. I’ll also have to figure out a good way to mount this bottom piece. (Worst case I will have to buy another set of carbon fiber rails)

Really hoping I can turn this into a super cool camera slider that people would think was bought from a store! Please let me know what you think, any advice/ideas.