FWIW - this is my experience from a diy CNC based on supported rails/screw drive.

Some info about it here: My DIY-carve

1 - Get Nema23’s in the 269oz range for all axis where the motor case will fit. Machine some Nema17-23 adapters if required.

2 - Get new drivers so you can take the motors to their optimal current limit (or get an Xcontroller)

These two mods are the two most signifigant changes to my diy CNC. (Started with Nema17’s and A4988/DRV8825 drivers)

Stronger belts are preferred as the increased motor torque may make the belts your next weak link. Screw drive will also be a big factor.

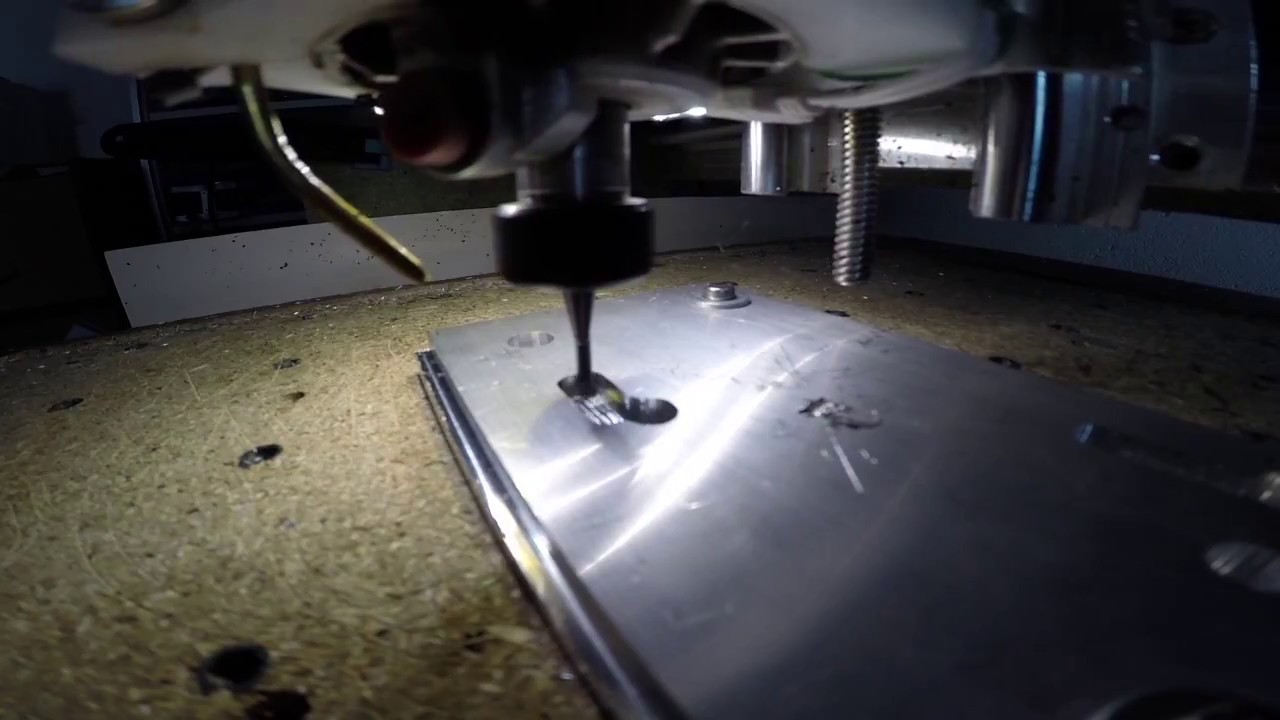

Video of mine in action (diy):

Fusion360 is very powerful once you get your head around it, it did take me a little while… ![]()