Is it me or am i seeing more issues assembling the 1000 x 1000 x-carve than anything else? Will there be dedicated instructions for the 1000 mm X-carve? mine hasnt shipped yet but i really would like to not endure alot of the build and rebuild issues i have seen on here so far…

You REALLY have to take your time with each step, I spent a lot of time bouncing back and forth between all the steps even the 500mm steps to compare and make sure I fully understood(the best that I could) each step before actually doing the step. I still screwed up and did some things wrong. i.e. the extrusions can be installed upside down even though the rail the wheels ride on is correct. Another step that wasn’t clear was when installing the support rails underneath the wasteboard you need ensure that you leave plenty of room on the left side of the board for mounting the drag chain mount, along with that they don’t tell you how to square the y extrusions on the board. Trial and error for me. Kinda like cutting a board, measure once, measure twice, heck lets measure three times, then proceed forward.

James

I’ve seen the upside-down rails mentioned a couple of times now. Maybe someone who has been-there, done-that can give us a few pics clearly labeled of the right and wrong ways it can be done?

I got this right, but by accident, as I didn’t realize the rails were not symmetrical. One side of the extrusion only has one slot in the side, that slot should be on the top, not the bottom.

So its upside down on the 4-sale page?

https://www.inventables.com/categories/machine-components/makerslide

When it comes to the installation for the xcarve the current way the extrusion is placed on the for sale page would in fact be “upside down”. I installed the left side y axis upside down and the aft x axis extrusion upside down. What did that mean for me? I had to turn my limit switches upside down for them to properly contact the post assembly screw, easy fix, just frustrating not to have a caution or warning when building the rails.

By the time I get mine you guys will have debugged the entire machine lol

We are pioneers!

I don’t have my X-Carve yet, but the makerslide picture that is linked appears only to be upside down for the gantry, looking at the instructions it appears to me that the rail is right side up for the Y axis.

Gantry

Y axis:

As I said, I don’t have mine yet but I want to make sure which one is correct for me and for anyone else reading this.

Mine are all in the same orientation as the x-gantry picture, and I didn’t have any issues with the switches.

I missed a few items since the video is setup for small X-carve not the larger version, I recommend just glance over the instruction the information is on the page - just me not looking for it …

A t-handle ratchet, and, T25 bit works wonders for the self-tapping screws.

For people assembling the 1000mm version, when it comes to cutting your belts, make sure to follow the written instructions to cut it into three equal pieces (~4ft each), as opposed to the video, which has you cutting them into 2ft sections.

In my defense, that was the first step I started with this morning, and probably should have had some coffee first… Just ordered another 4ft of 6mm belting to make up for my mistake, luckily it was pretty inexpensive ![]()

Also, if the Inventibles ppl end up making a second pass over those videos to add subtitles, I might recommend an annotation at that point of the belting videos to call out the correct lengths for 1000mm builds. Otherwise, everything’s been going very smoothly!

Many now have their machines and are at various stages of building their new toys! How exciting for us all. Thank you INVENTABLES for an excellent product, parts and instructions! Here are a few suggestions and tricks that made sense to me to mention here. I am not posting this to be critiqued, just sharing my journey. Please take what you can use and ignore what you don’t like. Feel free to add your positive thoughts on enhancements that will help others. Hopefully you can get an idea or two as some of these tricks I got from other sources just like us all. This post is focused just on the build of the X Carve 1000 x1000 machine, which I will now just call “1000X”. There will be another post focused on enhancements like and extras I added so far just trying to help new builders like myself.

BEFORE YOU START:

- Study assembly twice as much as you think you should. Watch all the videos AND read all the written instructions all the way through before you start. If you build as you go without doing this your likely to cut something too short or misunderstand a step. There’s not a video focused only on the 1000x, but by combining video and written carefully you can get very good instructions.

- Make a VERY big and clutter free space to build, with room for the machine, PLUS an area to lay out your parts and tools. There are many small Parts and Bags, don’t remove small parts from the bags just open them, and lay them all out with labels facing you. In your assembly space get a pad and pen for notes because as you’re building many ideas will come to mind. I used a VISE with padding to hold parts while I worked on installing pulleys, etc to the carriages. It made it very easy to keep everything steady and straight. I used a padded desk pad to lay out each step with counted parts from the instructions.

- Before you start realize you’re going to drop shit, it’s going to roll off into some black hole space you can’t find, and leave you crawling and cussing. So clean up the floor around you and make sure you have lots of light. I found it handy to take one of the Inventables boxes and use it for a “spare” parts box, so when I Had a few inches of extra cable or in my case some cut off extrusions it has a place to go.

Instead of throwing out a million pictures and steps of the build process I am only including tips and tip related pictures to add. I made my machine 1000mm x 800mm so I am definitely including how I did this with no problems.

THE WORKSPACE :

I built on to my existing bench along the wall. I made a torsion style table top without legs but with lots of support on 6” centers. Then I attached it to the bench with it overhanging, adding support beams and a sturdy extra leg/post. Basically, it will support heavy weight and abuse and won’t budge in any direction. I checked it for level throughout building it. A sheet of mdf is a great flat start but be sure the support under it is perfectly flat and shimmed to flat if accuracy of depth of cut on your CNC is important to you.

THE MACHINE:

Shrinking My X Carve – I started with the 1000mm works kit. When it came time to build the x gantry (the one with 2 parallel sections of maker slide, first I made sure the X Carve logo was on one of these pieces and was facing outward, either way is fine. Then I used a table saw with a Non Ferrous metal cutting blade to insure a clean square cut. I set up a stop block on the table saw (a stationary block attached to the saw) to reference each piece against so that every cut is identical. I only cut the pieces for the step I was working on but essentially I took exactly 200 mm off 2 pieces of maker slide and the two longest square extrusions. I also cut 200mm off the waste board width; drilled, counter-sunk and grooved new outer mounting holes just like the existing ones (see pictures). The Belts, wires and drag chain lengths changed too, but instead of trying to pre-cut or adjust cuts I just only cut what I needed at each step to insure I didn’t cut something wrong.

The belts kept slipping as I installed them so my fix was a tiny thin piece of black duct tape to help hold the teeth together along with the friction. I have seen folks use cable ties and shrink wrap effectively too, but the tape is easy to remove without damaging the belts and it holds and looks just fine.

Soldering- Man I hated steps on the soldering, even watched many videos, but in the end the bond I was getting sucked and looked terrible. Found these awesome jumpers at radio shack for a few bucks and used them to attach to the g-shield step. Out at the limit switches I used these nice little 22/18 gauge female quick connects that made a much more stable and attractive connection than solder.

On the wiring I didn’t add connectors like some have but I likely will. For the cable management I used a standard black plastic sleeve with a slit. I can remove them easy to get to wires and I think they look good to and protect well. Then I routed the wires coming off the X carve under the table and back up against the wall where I built a quick electronics cover of sorts. It has 3 sides, its open on the top and bottom for good air flow, the smoked acrylic slides in and out. The power supply and electronics are mounted to the pegboard in a friction fit top and bottom, with a piece of wood at the top that rotated to lock it into place. The top of the enclosure is notched for my computer monitor that will sit on top once I get a cable for it.

When you think your done – before you fire up the machine re-check your wires (a couple of mine came loose), check you V- wheels on each carriage (2 of these came loose on me too!) as far as adjusting the v wheels and the eccentric nuts I rotated the nut till all the wheels were just lightly contacting and rolling on the marker slide. Once you fire up the machine and the wiring appears good try to stabilize it and keep it from moving around. I bundled mine together then bundled them to a stationary point. I also snuggly attached my machine to the bench top with two screws on the perimeter. Using too many screws and bolting down too hard can lead to warping over time.

One last tip on the waste board. I used a product called Minwax Wood Hardener on mine to do just that, making the waste board stiffer and stronger. Happy Carving!

I got through about 80% of the build this weekend. I used “mise en place” bowls, and it was a huge help. At the beginning of each step, the instructions call out the parts and quantities. I would set up the bowls for that step, and when I was done with the step, it was easy to make sure I didn’t have any leftover parts.

Also, I ended up tapping my rails instead of using the self-threading screws, since I had the parts on hand to do it, but I’m sure that it really doesn’t make much of a difference.

I know that it has been a while since I put my machine together, but I am slow… slow in putting it together and slow in coming out with my “tips” post. I am also not an expert in this area, so I apologize in advance if I missed something or just plain got something wrong. Below are my assembly tips written as a letter to myself. I hope you find them useful as well.

Hi,

“Welcome to the word of”, X-Carve! (Futurama reference)

Congratulations on getting your 1000mm X-Carve Full Kit. I know you are going to love it. Here are a few tips I’ve got to help you on your way toward a complete and working machine with as few hitches on the way as possible:

If you haven’t watched the assembly videos that Inventables has provided, go and watch them all the way through before doing a thing. Trust me, it will help jog your memory later.

Some things to remember:

- Take your time. (I know you are excited to get carving, but taking your time now will save you time later)

- Work Clean.

- Wash your hands in-between each major section if not more (oils like to spread and make things slip that shouldn’t)

- Think ahead about clean wiring (this will help upgrades and trouble shooting later)

- Keep assembly area tidy (there are a lot of little parts that can get lost in a mess)

- If you don’t know then don’t hesitate to ask others and don’t be afraid to learn something new (ahem, soldering)

- Work in a well lit space

- Start the project in a place where you can leave it and come back and nothing will have been moved

- Knolling is your friend (I know it may seem like a waste of time, but it really will help)

Gather the tools you need:

You bought the Inventables Tool kit, so that will help you get started.

Here are some things that will help along the way:

- Needle Nose Pliers

- Diagonal or Flush cut Pliers/Wire Cutters

- T25 Torx Bit *

- Set of various other bits *

- High Torque Electric Drill

- Small electric screw driver

- Wire Cutter/Crimper

- Soldering Iron

- Handheld Screw Driver (with interchangeable bits/heads)

- Heat Gun

- Scissors

- Box knife (or something with a sharp razor like blade for all kinds of uses)

- Measuring Tools (as accurate as possible):

- Combination Square and level

- Calipers

- Measuring Tape (be sure it measures accurately… this will help with squaring your machine later)

* NOTE about various bits: Pick up the “Best Way Tools 100 Piece Screw-driving Bit Set” at Ace Hardware or other hardware store… they even have it a Bunnings in Australia and New Zealand. If you don’t have this gem, then trust me, you will find it very useful in the future.

or

http://www.amazon.com/Neiko-100-Piece-Security-Bits-Storage/dp/B000O5XDOG/

Gather the Supplies you need:

Inventables supplied you with most of what you will need, but here are some things that will help along the way:

- Heat Shrink tubing (a couple meters of various diameters… somewhere around big, medium, small)

- Solder (get the thinest lead based rosin core 60/40 Solder you can find and use it in a well ventilated space for lower melting points)

- Red crimp wire loop terminals 50 to 100 pieces. (the red ones should be a standard size and probably the smallest you will find at a general hardware store… get more than you need, because you will probably make mistakes crimping) **

- Small crimp wire spade connectors (small ones that fit on the spades coming out of the back of the limit switches) **

- Zip Ties of various sizes (but definitely small ones)

- Wire loom (I like the braided expandable sleeve kind)

- WD-40 or Tapping Fluid (WD-40 works just fine and is more versatile)

** NOTE about some of these connectors: by taking the time to put these on, later you can undo stuff for cleaning or upgrading or troubleshooting and the time you spend doing this now will save time later.

Begin Assembly:

- Have your instructions near (use a tablet type device if you have it)

- Read the step you are on and maybe the next step and look at the pictures before taking action (pay more attention to the words)

- Because you’ve already watched the videos and read through the instructions once already before you started you will be less likely to get confused

- Take it one step at a time an have faith in the order of things ***

- Knoll your parts for each step before you start the step or at the very least gather the pieces you will need into a small area or bowl (this will take a little discipline)

- Take your time Tapping the screw holes:

- In a small cardboard box off to the side, dip or spray the screw threads with WD-40

- Start with the provided T25 Torx driver and get the screw perpendicular to the end of the maker slide

- After the threads start to bite and you get a few turns into the hole, switch to a high torque power drill with T25 Torx bit on it

- Even with the power drill in hand, lightly squeeze the trigger and take the tapping slow. (just because it can go fast doesn’t mean it should)

- Use the handheld screwdriver when possible (this really will save a lot of time)

- When tightening the belts use 2 small zip ties to help secure the belts

- When wiring:

- test run each length before cutting the wire and leave a little room for movement/mistakes (this will help you get the most slack at the end)

- before soldering or crimping, ask yourself if you want heat shrink on it… (more than once you will make the mistake of not putting heat shrink on first and then having to de-solder or cut and start again)

- think ahead about labeling the ends with a bit of masking or painter’s tape (X, Y, Z, X-lim, Y-lim, Z-lim, spindle)

- think ahead about cable management (does it need to go through loom or drag chain?)

- Use loop terminals when wiring to the terminal blocks

- Use spade connector terminals when wiring to the limit switches

- At the end of each step, make sure you did it right before moving on to the next step (check orientation of the parts… are they right side up?)

*** NOTE about order of steps: You are doing the 1000mm kit so I would think about doing these out of order –

- Assemble the Waste board and support extrusions first and just not tighten them down too tight yet (this will be less unwieldy at the beginning than it will be at the end… you can tighten it all down when you are tuning and squaring at the end).

- Wire the steppers to the terminal blocks when you assemble the the X-carriage and Y-Plates (skip ahead in the instructions and read the bits that you need to do this then come back and keep on going)

- Same with attaching your limit switches but not wiring them

You Did it!

Here’s to hoping you had a great time putting your new X-Carve together. I know you’ll have a great time tinkering and making with it a lot!

Here are a few links that will help:

Sketch, that is an excellent write up and a big help to those just starting out on their “journey”

Hi all, I’m very interested in all these threads, and especially this one.

I agree with all what had been said here and before I start the wiring, I can add to advices:

- when tapping the Makerslides, don’t do it with the end plates as shown in instructions. It is really easier to do it with nothing else than the Makerslide and the screw. Tap all way long of the screw for all the holes then remove them to put the end plate.

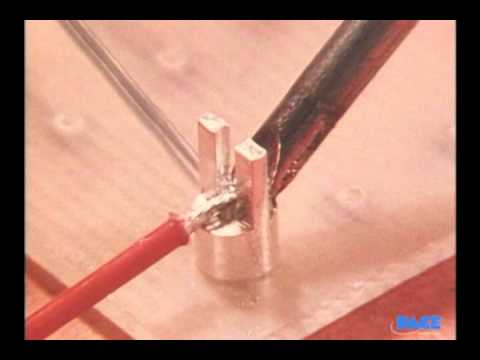

- I agree that it is not easy to put motors after Idler wheel especially with Nema 23 ones. And as I want to close my right and left sides with a wood or plastic plate (as I’ve seen it in a photo of an Inventables staff member), it is not possible to do it as Idler wheel screw go over the Makerslides. As shown in the photo, I simply mount Idler wheels with their screw in the other way, and it’s really simple to mount as all the screws go in the same way.

I have also sleeved and put terminals on all my cables!! But I just went to my hardware store and bought Paracord, cut it to the lengths I needed and then stripped the inside of them out to just leave the sleeve of the Paracord to use for my cables. I was able to get 2 different diameters the same colors so that was real cool! so here is what I have:

This is not going to be its permanent home so the cords are still a little mess, but once I get the work station built, 90% of the cords going to the PSU will be hidden. Here is were Im at with the Work Station: I have 3 coats wipe on poly on the top and 2 coats every where else and I put I coat of Paste Wax on the top. Next will be the red trim, 6 regular drawers and a file drawer!

That sleaving looks awesome! Way to go. It reminds me off the cloth insulated wiring in old automobiles. I’m also impressed with workstation, should serve you well, sounds like you have a lot of storage planned.

I’ll have to ember that trick with the para cord in the future, I ordered the skin Inventables had in stock for mine.