Hi all, Just got my xcarve all setup and cut a few test pieces and it was working like a charm, perfect circles and everything was being cut where it should have been.

This morning I started cutting a dust shield for the machine out of acrylic and all was going well so i went and got a cup of coffee and came came to a spinning spindle but no movement on the x,y,z axis. Thought this was strange, waited a couple of seconds nothing happened so I stopped the machine through easel and thought I would give it a second shot.

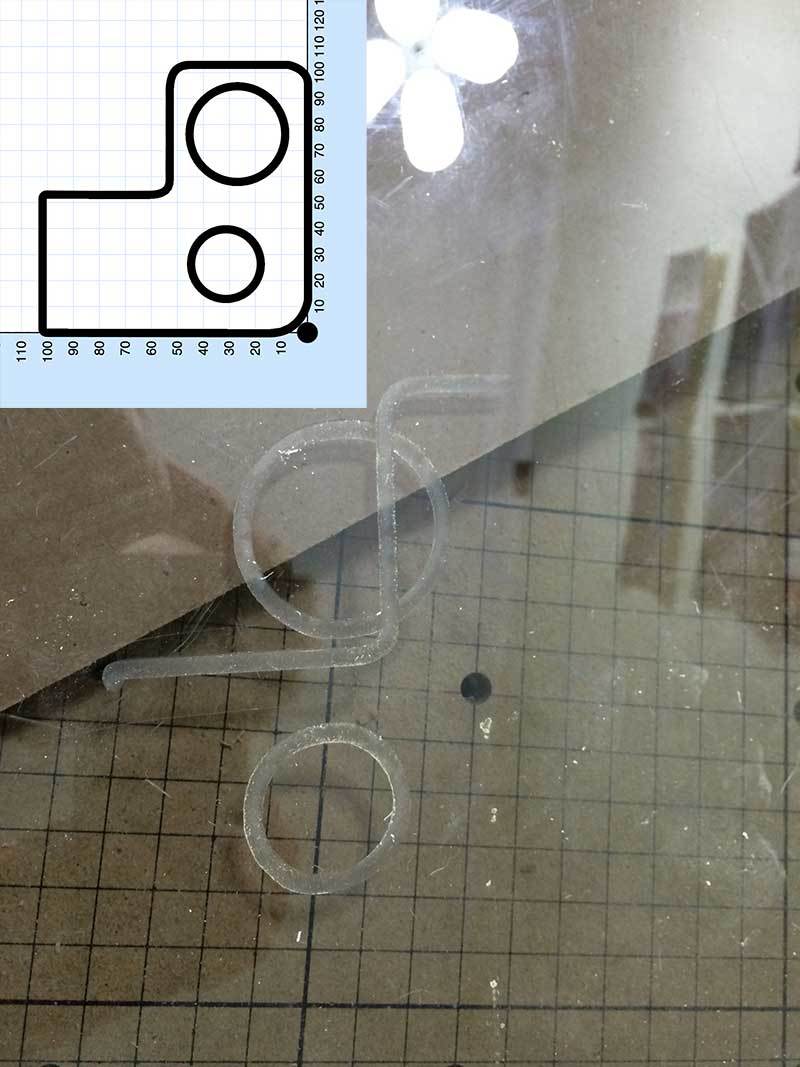

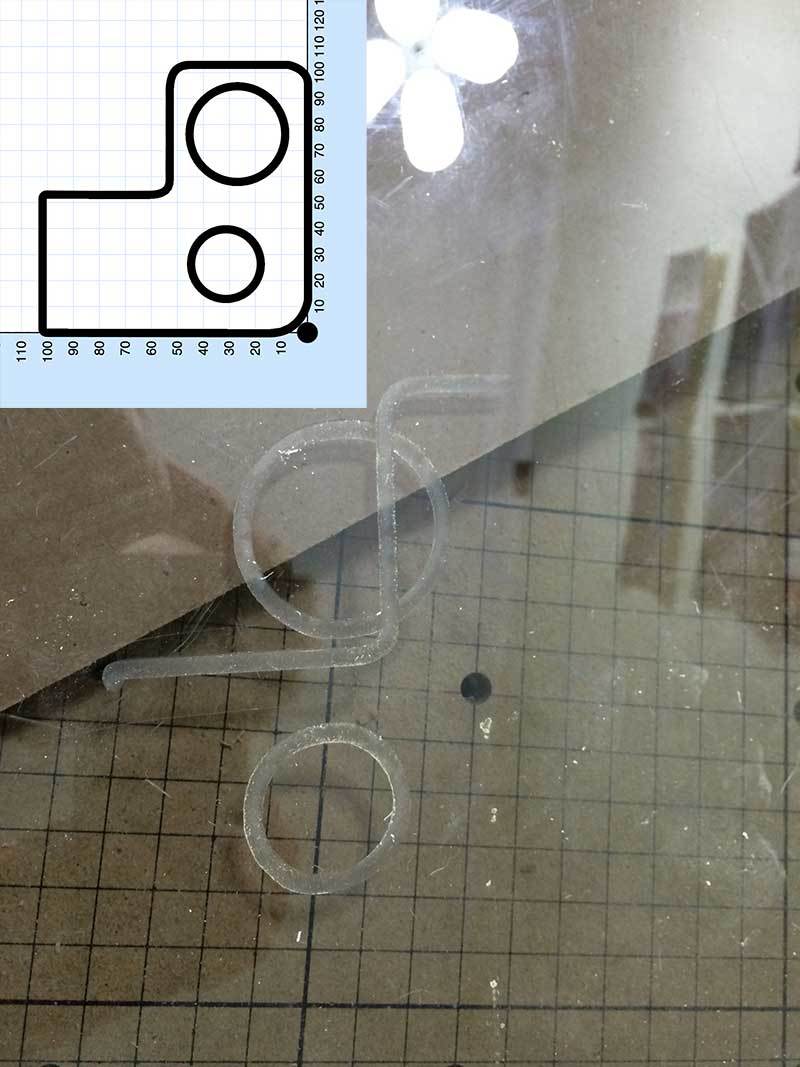

Now since this happened the machine has been cutting the correct shapes but its not cutting anything in the right locations. (see image bellow) its like the tool path is getting mixed up during the cuts.

Any ideas what could be causing this? I checked belt tension and wheel tension and everything is good ran the easel setup several times and I also checked all the wiring and nothing is wrong there.

<img src=“//discuss-assets.s3.amazonaws.com/4988c7f5d0603e1593872eda774852447c482ea615f9.jpg” width=“500”  height=“500”>

height=“500”>

As you can see its cutting things correctly but not on the correct path.

Any help would be greatly appreciated.

Jordan

http://www.JordsWoodShop.com

Well after a bit more fiddling I think I found the problem.

Check your V-wheels for any dust, as my both my X and Y carriages has acrylic dust jammed in the V wheels making it super tight at one point in its rotation and jamming the movement.

Since cleaning the wheels out my problems have gone away.

Hopefully this is all it was.

Jordan

http://www.JordsWoodShop.com

1 Like

I ran into a similar issue: correct path movement, but in the wrong place; but only occasionally… Tricky to pin down I figured.

But, after some fiddling with the Easel, I noticed that, when making rapid bursts of short movements (10mm) on the Y axis it sometimes got “stuck” (I did this by holding cursor-up after hitting Carve in Easel where you can move the spindle to home it). This stuckage is the root of the problem.

I think mine got stuck because of slight wiggle room of the gantry. If the carriage is, for example, on the left and the Y movement stops, the momentum of the carriage pushes the left side a bit further than the right side, at which point the gantry would slightly angle and get stuck, just long enough for the next movement to proceed unreliably to the next position (if moving at all) and G-code then just continues running in the wrong place.

The V-wheels checked out okay, so I resquared the machine on top of the work area, figuring that was not properly parrallel at the right distance, and again checked V-wheels. This greatly reduced the problem but did not solve it yet.

I started to suspect that my belt tension was too tight, feeling at the edge of stretching where it goes through the idlers and pulley. I readjusted the belt tension to make more of a “plong” sound rather than “pling”. Quite possibly there was a slight uneven tension in the two belts.

Since these tweaks I am now able to move the carriage all around the work area, with short bursts, without it getting stuck anywhere. Problem appears solved.

I hope this may help anyone with a similar issue.

you might also want to adjust your stepper motor current potentiometers along with belt tensions and squareness.

Ill echo what NickCook said - check to be sure your stepper motors are getting enough voltage. My first few carves worked fine, but then when I tried a complex design, everything went wrong.

After some troubleshooting and research online, I determined that the Y-axis motors were getting under-supply and stalling out when it needed to do rapid movements (like after it lifts the bit and moves to a new place).

This should have been part of the assembly instructions, but it’s pretty easy to test out - just go into Easel, pick any test carve and click the ‘Carve’ button. Once you are at the step where you can jog the machine, move the X-Carve all the way back and to the left as far as it can go, then change your jog increment from 0.1 inch to something large, like 5 inches and try moving the machine across the X and Y axis.

Before I did the adjustment, the Y axis would stall after moving a inch or so. It would never move the full five inches. I increased the voltage for the Y stepper motor a bit by bit until it was smoothly moving the full five inches.

WARNING: be careful when doing the large increment moves. You can crash your machine at the limits with only a few key presses. Be slow and deliberate when doing it, and avoid hitting the Z axis since that has far less range!

Anyway, increasing voltage on Y stepper motor (and verifying that X was good), solved the problem and my next attempt at a complex carve worked great.

1 Like

Thanks Tim! I followed your advice and tuned the voltage for the y-axis. That fixed the problem. Now back to designing!!

height=“500”>

height=“500”>