Hello everyone,

I just started using the Xcarve in a fablab, andd would like to know if it’s possible to make the CNC Xcarve do a groove on the side of a material and if so, which bit should I buy ? To be more accurate, I am cutting glasses shape with the CNC and need to make the groove inside which I will later insert the glass lenses. So the bit would need to cut in the profile of the material (see the pic attached

), leaving some matter above and under where the bit runs.

Thank you very much for your help, it’s precious

have a good day

Victoria

I think this is at least theoretically possible, but you would need a bit designed for cutting a slot like that. You would also need some pretty sophisticated CAM software. I’m sure Fusion 360 could do it, but the learning curve is steep.

1 Like

Xcarve don’t do that…you need a router and proper bit for that.

Maybe I’m not understanding what you’re asking but if you want to cut out material in the shape of glasses and then cut a grove for a lens then the XCarve can do that.

EDIT: I went and looked at a pair of glasses and I see the grove is cut inside to hold the lens, it looked just like a profile cut in the picture. I understand now.

1 Like

You need software/CAM that support the bit required.

You might be able to customize a bit to suit your groove profile?

Easel dont support such machining options, but Fusion360 as mentioned does.

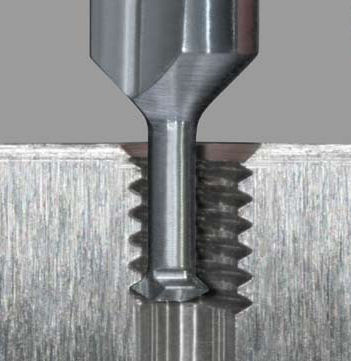

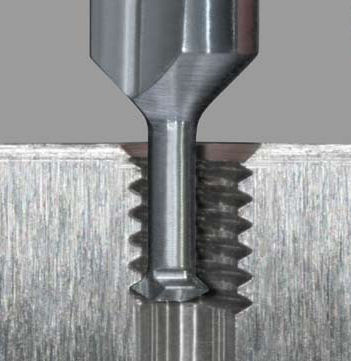

Here is an image showing a type of cutter that might work, thread milling bit:

1 Like

I have this Dremel bit. I have been intending to play around with cutting wooden threads ever since I saw a Legacy CNC do so at a wood show. My plan was to design a jelly bean dispenser and cut threads in a round hole so as to accept a mason jar. It just hasn’t bubbled up in my project list.

https://www.homedepot.com/p/Dremel-3-8-in-Grooved-Disc-High-Speed-Cutter-for-Wood-Plastic-and-Soft-Metals-199/100531863

I cut threads in wood lids for Ball jars using a cutter like Haldor shows above.

Hints; V Carve Desktop, ramped plunge, lead out then edit code.

The slotting bit you show would work as well especially for the slot in eye glass frames.

Just have to use lead in and lead out in the tool paths.

1 Like

I have this bit for my router

It works well in the trim router but the problem would be to create a toolpath that would move the bit to the right height in the hole then move sideways to the side of the frame then go around the inside of the frame, move away from the from to the middle before retracting.

I think it would be easier and quicker to make a jig on the XCarve to hold the frame then make an offset of the frame above the jig so you can use this type of bit in a router that has a guide bushing.

That’s a keyhole bit, but use it on a router and table. It’ll make quick work for what he’s trying to do.

Yes it is but I’ve seen a video where it was successfully used with a CNC router. I’m not recommending this because you need to know what you are doing to pull it off and have software that will support this…

Here is the video: https://www.youtube.com/watch?v=SblFFBq2bxo

The keyhole bit will work just fine in the CNC. There is even a Keyhole app just for this application. I use it all the time for my sign projects and have done several videos on this topic.

1 Like

You all have moved far away from the original question in the post.

The keyhole bit would make a very wide slot, likely too wide for the glasses frames.

2 Likes

@MarkA.Bachman depends on how bad your eyesite is…perhaps thicker lenses are needed.

his original post included a picture of how it’s done. I don’t believe he has that specific bit as shown though. he’s just wondering if he can do it with an XC because maybe he doesn’t have a router table.?

Exactly.

That image shows a frame with a narrow slot. That is not something that a key hole bit is capable of.

That was my point. There were those of us that said it could be done with specialty bit and special tool path.

Then someone went off coarse suggesting the key hole bit. Then someone followed up with a video link of a key hole bit making a key hole. Totally off coarse from the original question.

1 Like

Different bit types can be used for a variety of cuts with a little creativity. A small keyhole bit certainly could be used to make a side channel in a frame. Come in from the side and carve around or in this case, inside the oval shape for the glass area. Just takes a bit of imagination.

Many topics in this forum go ‘off course’ by those just trying to pitch in and help by providing alternative and/or imaginative solutions. CNC carving isn’t an exact science. I’ve discovered more than one way to carve materials into cool designs, etc. We’re all(mostly) here to help our fellow woodworkers.

3 Likes

One option to create the groove you are looking for, is to cut two separate pieces. Basically make a ring for the inside of the frame that can be glued into place to create the edge above the groove. This is a rough attempt to illustrate this idea.