I love my X-Carve. It has paid for itself times over, I’ve learned a lot, and it will always have a spot in my shop. But now I need to cut larger items out of 4x8 sheets and I need a larger format cnc. The longer dimensions scare me as far as stiffness is concerned. I know I am not the first to step out into something bigger without $10K or $20K laying around, so what do you guys think? Is there a 4x8 kit out there worth having?

MONSTER CARVE!!!

LOL

LOL, I know, right? Even if I could get the Y supported for that length, the X is a serious concern. My X-Carve has functioned so well, I just wish there was a good 4x8 solution that was less expensive than my truck.

Take a look at Gryphon CNC. Under $3k and Phil’s a good guy.

Evolution CNC looks really nice.

Make it as large as you need. One person made a 6’ x 13’.

Cncrouterparts.com has some nice ones as well.

That’s the one I am considering. Price is definitely an important factor. Just SO afraid of buying a cheap chinese cnc “shipped to a port”, so the Gryphon seems like my deal. I know there are people out there pissing on it (and that’s fair), but I may just take a chance.

I look at it this way… there are plenty of opinions out there from people who may or may not have even seen a picture of the product in question. I am not affiliated with Gryphon, but I know Phil a little bit and know he’s a bit obsessive about what he makes. I have not been to his shop yet, hopefully I’ll get the opportunity soon. The machines are definitely a step up from what we all have here, and can be open to mods which is something all of us avowed tinkerers love to do. And probably kind of hard to beat in price. Give them a look, report back with your thoughts, and maybe we can all learn something. I’ve been intrigued with his machines since I learned last year that he was building them, but just haven’t had the chance to visit and gab yet.

Well, after a lot of research and much deliberating, I finally made a decision. Getting started with the X-Carve 1000mm, I knew that I wanted to start out with $1K invested, and that is what I did. I bought a used one from the forums here for $800 + a Dewalt 611 and I was up and running. It has done me well and I have made my money back tens of times over in the last 1 1/2 years for my side project.

Now, I am looking to cut bigger, not necessarily better. If Inventables had a 4’x8’ solution, I’d be first in line. Since they do not, I began my search for a 4x8 CNC within my new self-imposed budget of $5K. What pissed me off in the whole process was that most vendors do not reference the TCO (total cost of ownership) only their piece. I get it, I do. They sell what they sell, you figure out the rest. It’s just annoying trying to keep track of what’s inluded with which solution and what isn’t - when trying to compare each option fairly and make sure ALL costs are weighed in. SO I set out looking…

Shopbot. One day. One day.

I looked at Fine Line Automation and CNC Router Parts. They look good, but when you add up the cost of something that you will be cobbling together yourself, you enter the cost arena of delivered machines from China and some go far beyond.

The {insert chinese company here} 1325 4x8 CNC starts to look like what I really want, at a price tag starting at $6700 delivered to my shop. (That is $4299 + FREE SHIPPING (to the port) on eBay + a dizzying amount of fees and surcharges that land you between $6700 - $8000.) I have no interest in spending $2K over my budget only to open a crate of body parts and the innards from a Mr Machine. I’ve used AliExpress for some grey-area arcade boards, but a full-sized CNC router? I’m not that brave, yet.

On the US side of things, a similar low-end machine like the 1325 can be had for around $9K -$11K. The vendors are too numerous to mention.

Maslow. Heheheh, had to put this in here. You got 2 bricks and $500? You got a 4x8 CNC. No.

Crawlbot. Um, OK. No way in hell. A $3K horizontal Maslow without bricks. No.

Blackfoot, I paused at this a little longer than I did the crawlbot, but not much. Made of wood raises an eyebrow, but chain-driven is the real problem. Reviews from real users are atrocious.

I looked at Gryphon, and all of the talk of CNCMogul aside, I just never had a good feeling about it, even after talking to Phil (who I agree is a really nice guy). Something about the setup didn’t sit right with me. It started out as the least expensive option, but when adding the costs together, I was sitting in the $4K-$5K range right along with the Zenbot. However, if you are considering a Gryphon, you should note that the prices are going up on Jan 1, 2018. FWIW

I had the hardest time deciding between The Gryphon and the Zenbot. Both were my only real options within by budget. Both had their downsides and their positives. After talking to Shaun at Zenbot and 4’x8’ owners, not just fanboys, but real owners with examples of their work. I decided on the Zenbot 4896 with the Gecko g540 4-axis control, and the steel stand they sell. I also picked up Mach3(from ArtSoft) and the UC100 USB Parallel Port Motion Controller(from Amazon). Now this purchase is not made without concerns. HDPE, no matter how thick concerns me. We’ll see. It has belts, another concern. However, with the tiny belts on my X-Carve, it did very well provided you know your feeds and speeds - so I figured I might be able to make it work. It has a 2 week return policy, which is a little short so I guess I need to build it fast. I purchased the machine with a Dewalt 611 mount, but Shaun is also throwing in an 80mm mount for the spindle I will be purchasing. I have no unrealistic expectations, only hopes that this will allow me to continue on as I have, but on a larger platform. We’ll see.

TCO on your final decision? I assume somewhere south of your $5k cap?

What REALLY pisses me off is forum posts that don’t discuss TCO! LOL

ZENBOT 4896,Dewalt 611 Mount,80mm Spindle Mount,Gecko 4-axis Control box,Steel stand, shipping to MS, USA - $4247.45

UC100 USB Motion Controller - $109

Dewalt 611 - $0

1.5kw 80mm Air-Cooled spindle (ER16 collet) and inverter - $255.

Mach3 - $175

(I already have 220v, a dust collection system, hoses etc)

TCO - $4786.45

How has your new Zenbot performed?

Due to Christmas and New Year’s plans(on both ends),I won’t be receiving it until the 5th or so. After I get it going, I will provide full info for all who care.

Honestly if your having a hard time it is probably because you lack some organizational skills. I’m not here to criticize, I’m gonna give you a great tip that applies to all data oriented situations.

Excel is your friend. Google has a free online cloud based version.

If you are careful to set categories and subcategories you can get some really accurate data and analysis. Feel free to pm me and I can send you a sample of how I calculated my profit/cost based on supplier per item and cost per screw per kit, with a live feed that as more orders came in I saw my costs rise and fall based on quantity.

@Phantomm, wtf?

Anyway, I did receive the email 4896 and the stand. The Zenbot is assembled and ungodly heavy. It goes on the stand next weekend. I decided that the 1.5 kw square spindle would be a better choice for mounting and cutting. Looking forward to providing a real update.

I believe I was replying to an earlier message. And didn’t add it into the header. I’ll do it now for reference.

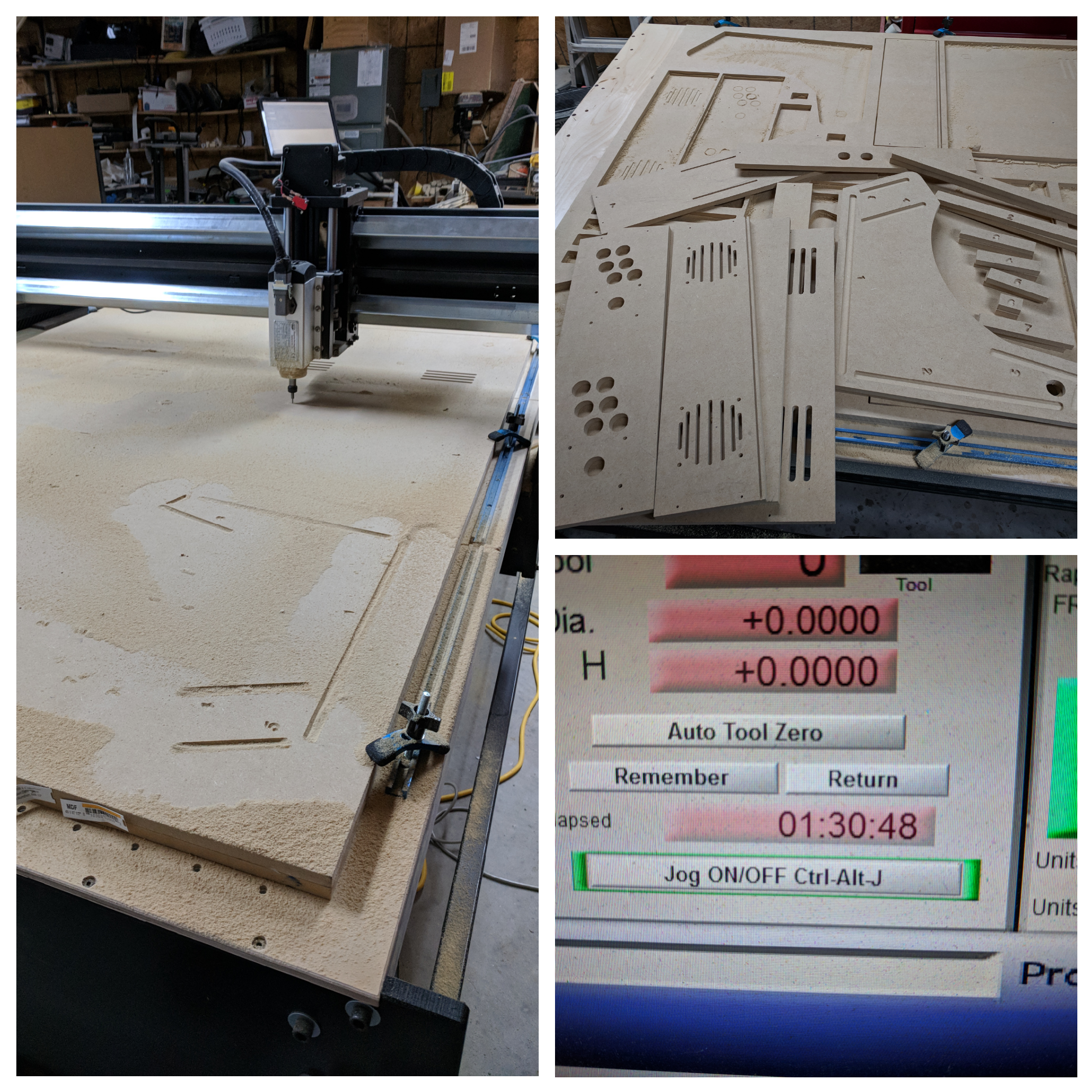

Anyway… I did my first run last night on my new machine. I find it funny that I thought I’d be cutting by January. Quick timeline: Zenbot4896 w stand purchased in early Dec, fully delivered in early Feb, cnc and stand assembled on 2 saturdays in Feb. In March, I was wiring the 1.5kw spindle, vfd, e-stop, configuring and testing the Gecko g540, and setting up Mach3 to run it all. Last night I did my first test run.

I ran the cuts at 200 ipm with rapids at 400 ipm, 1/8" straight bit cutting 1/8" per pass. I chugged along for 90 min flawlessly.

Lessons learned-

Zenbot:

Obviously a small company. Kits are well thought out and designed. Maybe too thought out. My X axis belts were cut 'to the tooth" only as long as they needed to be(unhappy while clamping). You will not get updates while waiting or a time frame. That said, Shaun was EXTREMELY responsive to emails and willing to help. Everything fit well and overall I am extremely pleased with the kit. Much like the X-carve, the Zenbot has a clamping screw grid in the baltic birch top. However, after I layed a full sheet down, all clamping points are covered. I just removed the table top side screws and screwed T slot down the sides. While the 4896 stand was a convenient buy… If you are of the inclination, you could easily make your own.

Huanyang 100v VFD and 1.5kw “square” spindle:

OK, there is a lot of contradictory information out there. After sifting through most of it, I was able to get it running well. A Belden VFD cable was a must. I have the vfd settings if anyone ever needs.

Gecko g540:

The g540 box provided by Zenbot needed to be modified to add in another DB9 port to allow for an E-stop switch and to control the spindle. After proper configuration it works well with the VFD and spindle (no external relay needed).

UC100:

The UC100 is a usb to parallel port controller that works well with Mach3 and the g540. Download the drivers and install. (Oh and beware of knock-offs, this is a controller not just usb to parallel converter)

Mach3:

Really powerful and does a lot. That said, there is a TON to configure. It all makes sense once you get into it, snd there is a lot of help out there. Do a lot of reading.

Going forward-

Since I can cut more, faster, the Zenbot will be my primary CNC. I am looking into the laser upgrade options for the X-Carve (currently thinking about the PLH3D 6w from Optlasers. We’ll see.

I bought a Gryphon. Now I am looking for replacement parts. Anyone that has one have any links?

I do have two x carves as well, but got the gryphon to do 4 x 8 foam and mdf carving.

What parts do you need to replace?

https://discuss.inventables.com/t/gryphon-and-x-carve-compatability-of-parts/55941

I believe this is the answer.