Right. Can you skip the auto-homing and jog the spindle to the lower left of the stock and set that as home? It’s the way I worked most of the time.

@StewartAllen I had the same problem Neil was having regardless of homing the other day. Despite stock and zero settings, it always centered my stock in the middle of the work area as opposed to lower left. I eventually just changed the machine bed size to that of my stock to overcome the issue.

@StewartAllen My point is that when my part is in the center of your workspace, the code produced sets that location absolute. Basically if my part is at (100,100) in Kiri:Moto, the code will send it to 100,100 from my desired 0,0. This happens regardless of stock size. If I set up a job on the Shapeoko XXL in Kiri:Moto and tried to run it on a regular Shapeoko, it would run the machine past its limits. I could work around by setting my stock origin to 100,100, but that doesn’t seem natural.

I also just noticed that when I set my stock height taller than my part(say 30mm on a 7mm thick part), the gcode sends the tool first to the bottom of the stock, then lifts to cut the top 7mm. That would be a disaster. Am I missing something? I’d love to use the tool as the interface and ease of use is fantastic,

Thanks again.

Clearly something is amiss. Do you have “origin top” checked or unchecked? Regardless, it should not do what you’re describing. Let me test a few things and see if I can figure out what’s up.

I had origin top checked.

@NeilFerreri1 sorry. been traveling and not much time to focus on this. will repro and hopefully fix this week.

@StewartAllen No need to apologize. I wouldn’t even bother posting here if I didn’t see the value in what you’re doing. Let me know if you want me to try something else.

Thanks

This should be fixed now. When ‘origin center’ is unchecked origin should be 0,0 and not offset by half the size of the bed, which was the previous behavior.

Hi, this looks like a really useful project. I’m trying to mill a part with only horizontal and vertical surfaces, however I’m having some trouble.

Roughing and Waterline already auto-adjust cut-down levels to exactly clean flat surfaces.

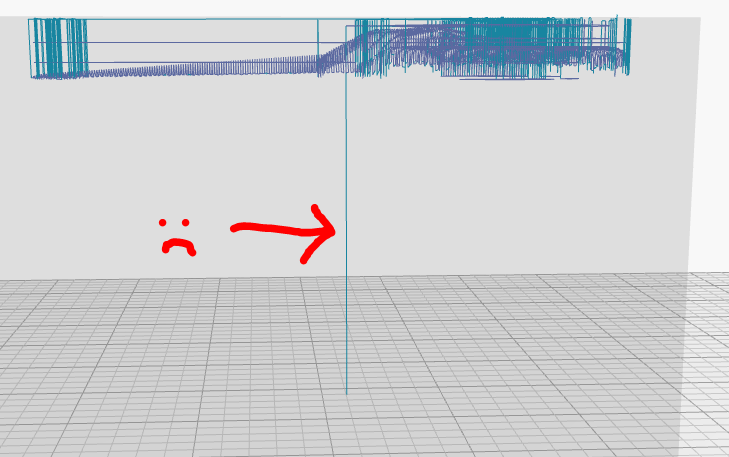

This function does not seem to work as expected (see picture). Am I doing something wrong?

Best regards,

Christoph

When you enable finishing, does it detect and clean the flat surfaces properly?

Do you mind sending the STL to sa@grid.space ? I’ll take a look and see what’s up

Hi,

Is something wrong with the domain?

I get an error when trying to connect.

debugging now. the server is up, but cloudflare disagrees.

resolved! sorry for the trouble. the disk cache was full and the error went unreported.

Great Job!

@StewartAllen I just came back to check out your tool. I am still seeing an issue when the stock size is set. The first rapid move should be at a safe height, but it appears that with any stock that is greater than the height of the part it will do a rapid move to the safe height as if the part was at the bottom of the stock. For example, let’s say I had a part that was 10mm in Z height, a safe height of 1mm, and my stock set at 50mm height. I’d want my first move to go to whatever XY at a height of 1mm. I am seeing that the first move would be G0 Xwhatever Ywhatever Z-39 Then it goes on to plunge UP to Z-2 or whatever.

Does that make sense?