Hey John, sorry I jump between. You’re saying Sketchup is free program. I tried couple of times, downloaded but, giving options for fees. How did you do that?

you can also check out fusion360… but there is a large learning curve there… its along the lines of solidworks which is what the pro’s use. the engineers used it where I worked to design all there parts. There are some good videos using 360 on youtube @ NYC CNC

for scetchup basics… you can check out Jay Bates he has some good walkthoughs for woodworking. And he does a few X-carve videos.

Dan,

Maybe you already understand G Code from the above answers, but I’ll give an analogy that may help using desktop publishing and using a postscript file being sent to an offline printer.

To make a document, you use any sort of “design” application, whether that be a word processor, paint program, even CAD. Once you have your design completed, by clicking File -> Print, you are basically initiating a post processor algorithm that builds a postscript file. Sure with some systems you can send this directly to a printer, but in this case, we are saving the postscript file to disk.

There are some similarities between postscript and GCode. They both are standard machine control languages that are stored in ASCII files. G code is a industry standard also called RS-474 and ISO 6983. You can open either file in a text editor, ala notepad or vi, and read or edit it.

Now, to actually make something, you need a way to transfer the postscript file to the printer. If sending to a print house, you may package the file onto an email, or copy it to a thumb drive and insert it directly to a port on the machine. ince printing is such a common activity, print queues are standard in most systems and so the transfer is is almost magic in that it just happens, without us recognizing the HOW it gets there. In our case, the communications protocol is a serial stream over USB. The arduino drivers you are instructed to install, include the device driver to establish the serial port over USB communications and make it appear as a standard COM port.

Since it is a standard COM port, you technically could just cat the gcode file to the com port, but since the grbl software running on the arduino processor only has a small buffer, and it processes the commands line by line, that would over run the buffer and commands would be lost. The various processes such as UGS (universal G Code Sender), Chillipeppr, and even Easel, have code built in to interpret the flow control signals being sent from grbl to prevent that overrun.

Just as the printer engine intreprets postscript and commands the laser to move, or the dot matrix to fire, grbl intreprets the gcode file and sends an appropriate sequence of pulses to the stepper motors to make them move the router. grbl has some settings stored in flash memory that allow it to calculate how many pulses to sent to move the head a certain distance, how fast to send the pulses, etc.

Hopefully that makes sense now that the project stream is to design in some application, post process that to generate a gcode file, send the gcode file to the machine, and have the machine intrepret the gcode into motor control pulses.

–Rick

I too was having trouble with the learning curve until I purchased VCarve Pro. Now I can design something simple and generate some gcode in under an hour. G-wizard Feeds and speeds calculator is a huge time saver as well and takes away most of the guesswork of figuring out feeds and speeds. As far as controlling my machine and sending gcode, I’m using Chilipeppr which is awesome and free.

After reading all of these posts I have decided to try the VCarve Desktop software. I really like that you can upgrade to the Pro version later with no financial penalty.

I forgot to give the specs on my X-Carve which I know can impact some of the advice. I have the 1000x1000 model with limit switches, a Dewalt 611 router, the nema 23 step motors, ACME lead screw, and the arduino controller. I have purchased a few different bits from Inventables as well as drillman1 on ebay that were recommended by people on this forum.

You are absolutely on good track.

hi…

I’m the crazy uncle over here on the bottom limb of the Inventables family tree — for software, I use 2 things:

HeeksCAD (free)

Universal G-code Sender (free)

If you have ANY experience with CAD (CAD is simply a 2D drawing program used by engineers, but don’t let that scare you - CAD drawings are saved as a “.dxf file”), then HeeksCAD is a logical step to 3D. If you can draw a DXF file in a CAD program (I use LibraCAD - also free), you can IMPORT (not open) DXF files into HeeksCAD and make a 3D model (by extrusion).

There are about 6-7 really great videos on YouTube (about 10-15 minutes each) that will teach you HeeksCAD. (I learned it using the tutorial below on a rainy Saturday afternoon)

HeeksCAD will also generate the G-code (and show you the cutting paths). This is where Universal G-Code Sender (UGS) is needed. You open UGS, Connect to your Arduino (virtually and physically), open the g-code file and tell UGS to “send.”

I have made some pretty cool stuff so far - 2 different gears, a picture frame, and a centrifugal pump impeller… and that is the ONLY 3 things I have made since I started carving a few weeks ago.

One other product I use is called OpenSCAM (don’t let the name intimidate you). This is a g-code modelling software. You open your g-code with it and it will show you EXACTLY what the x-carve is gonna do when you send that G-code… This really saves material/time/sanity…

1st tutorial of a series on HeeksCAD:

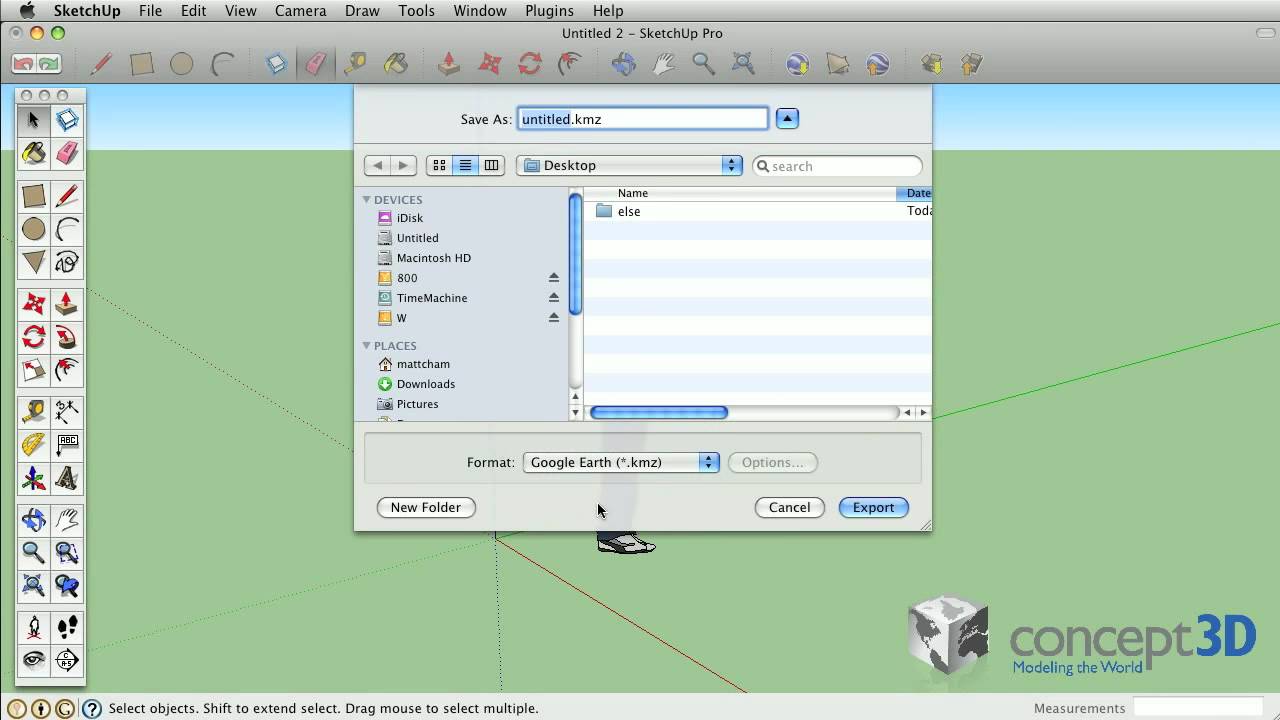

The Sketchup folks make it as confusing as possible! What you want is Sketchup Make

You can download it here http://sketchup-make.en.softonic.com/

Sketchup Pro is the one that cost money, Sketchup Make is free

Here is a short video showing some of the differences

I wanted to check back on you. Would it help if we put together a list of projects in order of increasing complexity?

For example:

- Plaque that you engrave and paint

- Coaster with wood inlay or a make a puzzle

- Epoxy Inlay - Technique that can be used with your art

- Make a 1 color stamp or more complicated 3 color block printing

- Wine cork holder - A project that has you make a box

- A box of an arbitrary shape

- 3D iPhone case using Easel* stay tuned for updates on Easel’s capabilities here

- Pinewood derby car demonstrating 3D shapes

- Leather working

- Quadcopter

I’m very interested in your feedback.

i know your frustration learn easel first there is alot that can be done with it. i started off with easel till i felt confident to take the leap into something more involved like learn some basic gcode commands. then i started learning how universal gcode sender operates it takes some time but if a hillbilly like me can do it anyone can

here are some links to check out

these are some of the things i use when working with my cnc

TBH I haven’t touched my X-Carve since I made my original post. I didn’t want to add the cost of V-Carve to my CC until I have the X-Carve paid off which has actually happened this month. I’m really undecided what to do because so much of my initial excitement has worn off due to my inability to make sense of the software. Not being able to do all the projects that I had originally planned while waiting to get my machine has kind of changed my perception of the X-Carve from a good thing to a bad thing. I know it’s not fair after such a short time but I work a second job to earn my play around money and the thought of spending another $350 for V-Carve doesn’t have much appeal at the moment. I also have a Y axis stuttering problem that is making it lose steps but I just haven’t been motivated to look into. Sorry guys, it’s all doom and gloom around here.

Easel appears to me to be all but useless. I can’t see anyway to do anything other than carve some goofy pre-loaded shapes. Anything I try to import either has errors or it says it can’t carve it for any number of reasons.

Hi, Dan.

Sorry to hear about your experience with the X-carve to date. One of the problems with a very flexible machine is that there is a steep learning curve to get it tuned and working for you. If you can hang in there you most likely can do those projects that you wanted to do.

The Y axis stutter is a common problem and is usually not too difficult to solve. It is most likely one of the following items: loose pulley set screws, belts to loose or too tight, loose wires, current limit potentiometer settings, or mechanical binding on the MakerSlides.

You can look through the training materials at Vectric to help you with the learning process for Vcarve to see if it will do what you want to do. You can’t carve with it, but they do allow you to download a trial version that you can play with to get more familiar with it. Here is a link to the training material New To Vectric | Vectric

I didn’t bother with Easel as it didn’t fit my work style.

There are people here that will help you as well as the people at Inventables if you want to get your machine working.

@DanWard, you may be able to fix your Y-axis stutter very easily. Check for loose set screws, loose wires, and binding like @LarryM suggested. If you don’t find anything there, search for “maintenance videos” to see a couple I made on belt tension and potentiometer adjustment.

I was having a problem importing SVG’s as well. A friend of mine taught me that if you go to www.makercam.com, open the SVG and then save it from there, it will usually open in Easel. I’m not sure why it works, but it’s a 2 minute process that has opened up a whole world of SVG’s for me.

As long as you are happy with step cuts in your carvings instead of slopes, you should be able to make Easel work until it’s earned enough to make V-Carve worth it. Don’t give up yet, we’ll help you get over this slump.

Your experience worries me a bit as i have no knowledge either and placed a order recently. It would be cool if inventables did another blog post about Cam/Cad like they did for milling 101. and a projects list of growing complexity sounds helpful. Meanwhile i’m looking forward to the shipment.

Hey Zach, What would be really helpful is step by step involving getting UGS or software other than Easel to work with XCarve. And providing links to the right places for help when things don’t go right would be great.

I spent the money both on the XCarve machine and on Vcarve Pro. I am extremely disappointed that it is all so difficult.

Vcarve Pro is good all the way to saved toolpaths but getting it sent to the machine to cut is the issue.

I first cut a project with Easel well over a week ago and every day since I have spent a lot of very frustrating hours trying to get Universal Gcode sender to work with my Xcarve.

I have downloaded Java, and UGS.

UGS opens but it can’t seem to find the machine. Yesterday it told me there were no drivers on com port 3, today it tells me that Grbl has not finished booting.

Easel then from the same connection promptly cuts what I tell it.

Finding the right help is so difficult.

Putting the machine together was a breeze thanks to your great tutorial. You guys sold me the Vcarve Pro providing a tutorial on getting it to talk to the machine would be an absolute winner.

Thanks for listening.

regards, James

@JamesBurton thanks for that feedback. I can appreciate that it must be super frustrating if you aren’t able to get UGS to function properly.

Inventables doesn’t own UGS or support it formally. It was written by an awesome guy in the community named Will Winder who is a software developer that did this as a side project. He designed it to be cross platform so he’s hopeful that it would be working for you. I just checked his github page and there was an update 4 days ago so you might reach out to him to see if he can help you track down the problem you are experiencing.

Inventables made Easel to solve the problem you are experiencing right now. As you can imagine it’s a bit harder to solve than it would appear at the onset when you get into the details. Basically we wanted to be able to plug in, click carve, and have it just work.

We have a team of engineers and a designer dedicated to Easel and we improve it a little bit each week. Sometimes those improvements are immediately obvious and sometimes they are longer term improvements that users won’t see for awhile. We are on the cusp of delivering one of those longer term improvements that will make Vcarve Pro compatible with Easel. You will be able to export from Vcarve Pro and import into Easel.

If you can be patient on this one I think the new Easel functionality will serve you better than a blog post. That being said we are rolling it out in phases because it is a very complicated feature with lots of “gotcha” details. Our software engineering team gave a demo of it last week at lunch and everyone at Inventables is very excited.

For UGS, give this a shot:

- Unplug your arduino and reboot your computer. (Yeah, I know. But try it).

- Do not start a browser. No browser. None. Not IE, not Safari, not Chrome, not Firefox, not Opera, not lynx.

- Plug in your Arduino USB cable.

- Take your hands off the mouse and keyboard and hum the first ten seconds of a national anthem.

- Now start UGS.

Did that make a difference?

[Serial ports over USB are touchy, finicky nasty things. You’ll find that trying to use Easel and UGS together is painful. You’ll also find that UGS isn’t very happy to start up when the Arduino isn’t already booted and ready to go. Usually quitting UGS, unplugging the Arduino, wait five seconds, plugging in the arduino, wait five seconds, start UGS will work.]

Been a while since I saw Lynx browser

Maybe we can form a support group for all the X-Carve owners that can’t figure out how to use their machines  We can have monthly meetings on Skype where we each stand up and say “My name is **** and I’m a moron. It’s been 11 days since I carved anything”. One of the smart people on this forum could carve us coins to celebrate milestones like "200 Lost Steps"or “5 Destroyed Clamps”.

We can have monthly meetings on Skype where we each stand up and say “My name is **** and I’m a moron. It’s been 11 days since I carved anything”. One of the smart people on this forum could carve us coins to celebrate milestones like "200 Lost Steps"or “5 Destroyed Clamps”.