So, a few weeks back, Jennifer Chepurny dropped me a line and asked me if I’d be interested in playing around with the proposed new version of the SuckIt dust boot. Well that didn’t take much time to decide on, a chance to try out new gear! Electrons had barely settled on the email before I said I was all over that.

Before I even start here, for transparency, I received this upgrade for free, in return for my input on the design and utility of the new variation. I have tried to be as objective and fair as possible.

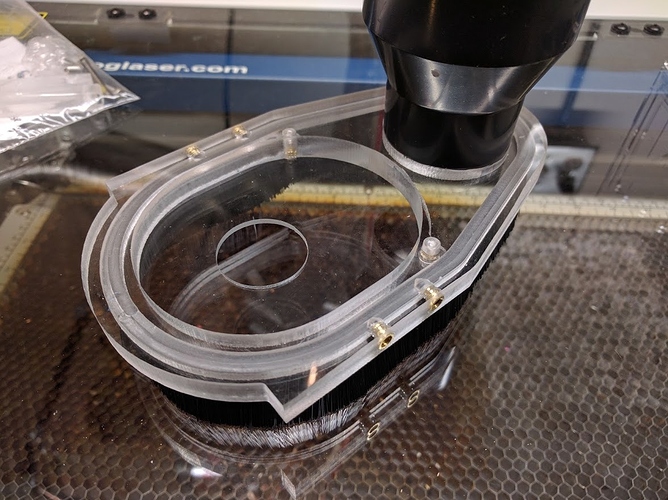

A couple weeks later, oh look, a box in the mail! The boot came in its component parts, with the threaded inserts already installed, and it took me perhaps ten minutes to get it all assembled, about three minutes of which was taken up finding my allen keys to install the magnet-holding slides. The slides are not shown in these two pictures, I added them right after I took these. The only problem I ran into during assembly was that the magnet-holding pockets in one of the slides were not deep enough to actually hold the magnet in place. I resolved that by just removing one of the (identical) magnetic slides from my existing one, and moving it over.

Before I popped it on the router, using the exact same brackets as my first version, I weighed the two of them. The original version weighs 6.4ozs according to my postal scale, the new one 5.3, for a savings of 1.1ozs, or fully 18% of the V1’s weight.

The most obvious feature of the new one, aside from the weight-reducing, tapered design is the cutout for the router. By cutting through the thick portion of the shoe and adding a thin shield at the bottom, they have created a version that addresses my only real problem with the V1 variant: How much depth capability it took off of the router. With this version, the collet can touch the workpiece before the router body touches anything on the shoe, giving that entire range of motion back.

For scale, here are the two versions of SuckIt, and my previous KentCNC router-mounted boot.

I won’t talk ANY smack about KentCNC at all, they’re awesome guys and they bent over backward to make that boot as good as they possibly could for me. They changed out bristles on it once for softer ones, sent me a new lower shoe, and spent quite a lot of time talking with me trying to get it just right. The weight and stiffness of the bristles, though, was always a problem and resulted in uneven surface finishes on the bottom of pockets, no matter how carefully I set it up or what they did to help. I think it’s rather unavoidable, given how flexible the X-Carve’s X-gantry is. It also weighs considerably more than the SuckIt, although a direct comparison would be rather pointless since the weight is held so differently by the structure. Suffice it to say, I think that SuckIt in either version is a superior dust shoe to the Kent design, which is a shrunk version of one intended for a much larger, stiffer CNC.

With the assembly complete, it was onto the X-Carve with it!

You can see how the cutout lets you get lower with the router, this is about down to where it would have been in contact directly before, and you can see here that I could easily go down another quarter-inch or so, which would easily touch the collet to the workpiece.

The new shape is very apparent, and feels a lot smaller than it physically is. Dust collection is every bit as good or even a bit better than the V1, I think. I was worried that the smaller intake might make my dust collector less effective, but it doesn’t seem to have had a negative effect at all. The waste board in this picture was cleaned off casually just before I started the carve that is shown complete there, and the workpiece and work-space have not been touched since the system turned off. This picture was taken about fifteen seconds after the bit stopped turning. Ignore the dust in front of the stops down on the table, that is about fifteen parts worth and wasn’t cleaned up at all before the test. The collection was quite good!

Overall, I am extremely pleased with this variant of the SuckIt. It’s definitely an evolution of the previous design, no really earth-shaking innovations, but the improved “cut away” design deals with what was for me the only major downside to the V1. The weight reduction is nice, but not critical by comparison, and to my eye the aesthetics have improved with this version as well. Aside from that ONE piece not being quite deep enough to hold the magnets, this “prototype” version is what I would consider a good-to-go product.

Thank you Jennifer for giving me the chance to test this one out! I’ll be keeping this thread updated as I work with it more, and post my thoughts and oppinions as I gain more spindle time with it. So far, I am extremely pleased!