Hi Folks,

Firstly let me apologise if this has been posted in the wrong section, it seems to be the most appropriate in my mind.

Since assembling my 1000mm Fully Loaded Xcarve, I have noticed that when I initiate the homing sequence that there is some kind of ‘glitch’ when homing the Z axis.

I can only really describe it as the stepper motor slipping on its internal mechanisms because as far as i can see, there is nothing catching on the gantry and the ‘glitch’ occurs at different heights everytime i initiate the homing sequence.

I have included a video that i recorded onto youtube so that people could see for themselves.

Any input would be greatly appreciated.

Check your pulleys. And to quote Phil, “make sure you use BLUE LOCTITE on all the set screws!”

Thanks MarcCohen,

The pulleys seem to be fine, the belt is not slipping at all, that was my first assumption. The horrendous vibrations seem to be emanating from the stepper motor itself.

Are you using an X Controller or the old arduino based system?

Its the XController buddy

Then I’m at a loss. I watched your video and it still looks like a slipping belt to me, but I’m just a newbie. Some of the other experts in here will probably get back to you shortly.

Thanks for the input Marc, I’m a newbie too! All suggestions are greatfully received

I’ve had that happen before. Fixed it by readjusted the Z-Axis V-Wheels. It looks like at that one point they might be too tight or misaligned.

Steve…

I had the exact same problem with mine.

The belt is not slipping and it only does it on the UP movement.

- I took the router out of the bracket.

- I removed the 2 delrin nut screws.

- checked the Z carriage for proper tension and alignment.

- Carefully re-tightened the 2 delrin nut screws making sure that I was tightening them down equally.

- I put some graphite lube on the Z axis screw

The problem did go away.

However, my machine is in a very cold pole barn shop, and I believe the problem lies between the cold temperature on the delrin nut, and the Z stepper may not be quite strong enough.

when I first go out there it will still wants to make the grinding noise.

after I run it up and down a few times it will work fine.

Thanks for that advice Jan,

It sounds almost if not exactly the same problem i’m having. The kit came with some lubricant but no indication in the assembly instructions as to where it should be used. I will slather the ACME screw with lubricant and see how it fairs.

Many thanks and have a great Christmas

J

yes, I received the lube packet also.

but I’m reluctant to use it because it will be a dust magnet.

that’s why I used the dry graphite.

I have 190K heater in my shop, and when it gets warm in there the Z axis works just fine.

I’m confident when the temperature warms up, all will be good.

Good call! I wouldn’t have factored in the dust issue! I too shall use the graphite option.

Did you adjust your pots? The newer Xcontrollers did not have the pots adjusted at the factory/Inventables and the instructions call out for pot adjustment. My Z axis did similar until I adjusted the pots.

I agree.

The new Xcarve 2.0 instructions originally said specifically that you don’t need to touch the pots (I think the upgrade said only if you weren’t moving the Y motors to their own driver). Then magically one day, they changed to have detailed instructions for setting it. Someone that got like the second batch of Xcontrollers pointed that out in a thread one day and it amazed me.

Maybe its a lower cost to not have the pots pre-set at the factory and they weren’t having to bring them in-house for testing anymore?

Justin,

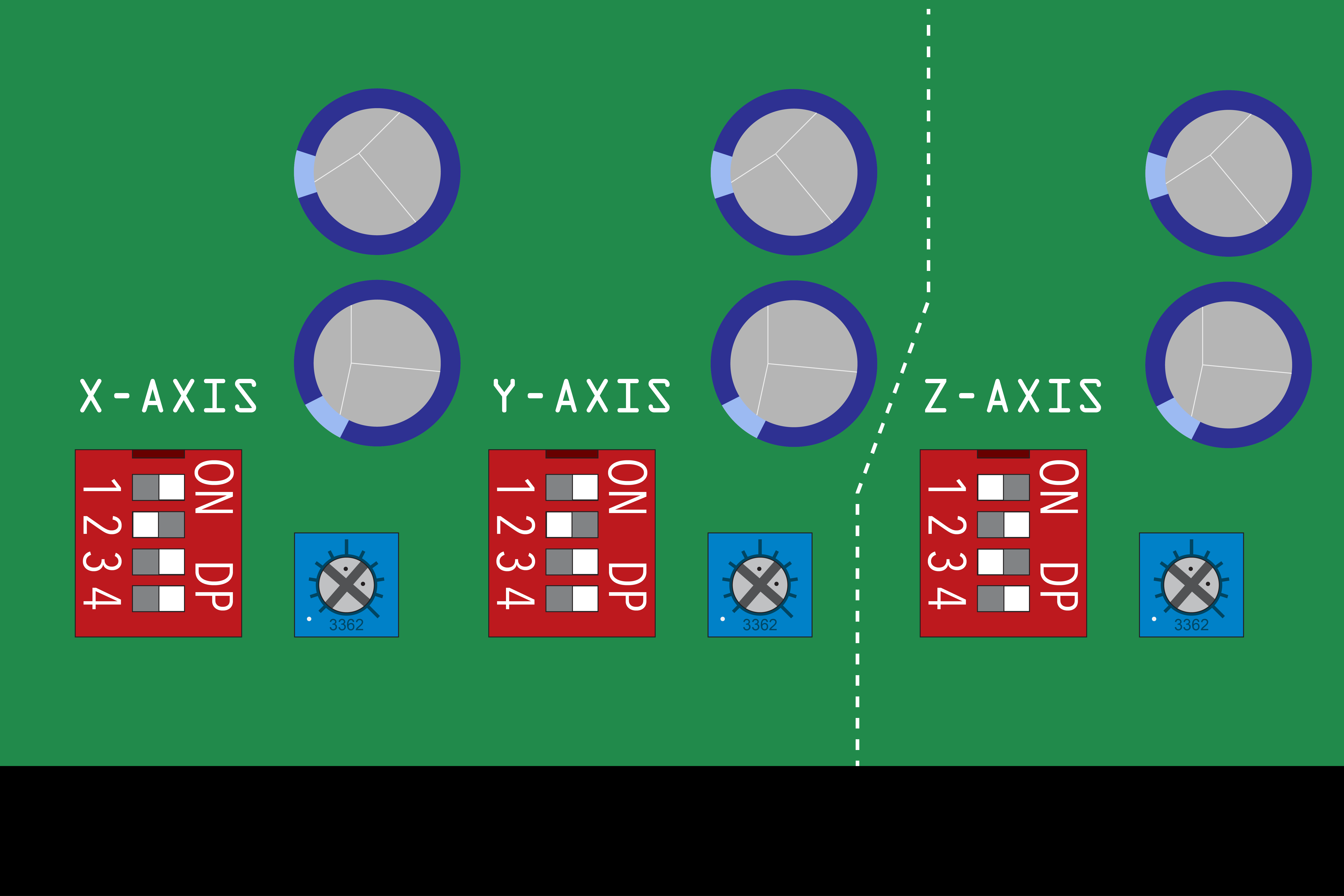

What position did you set them?

when I built mine, they were set at the 2 o’clock position like the instructions says.

I’m not an electronics genius so I’m reluctant to start making changes.

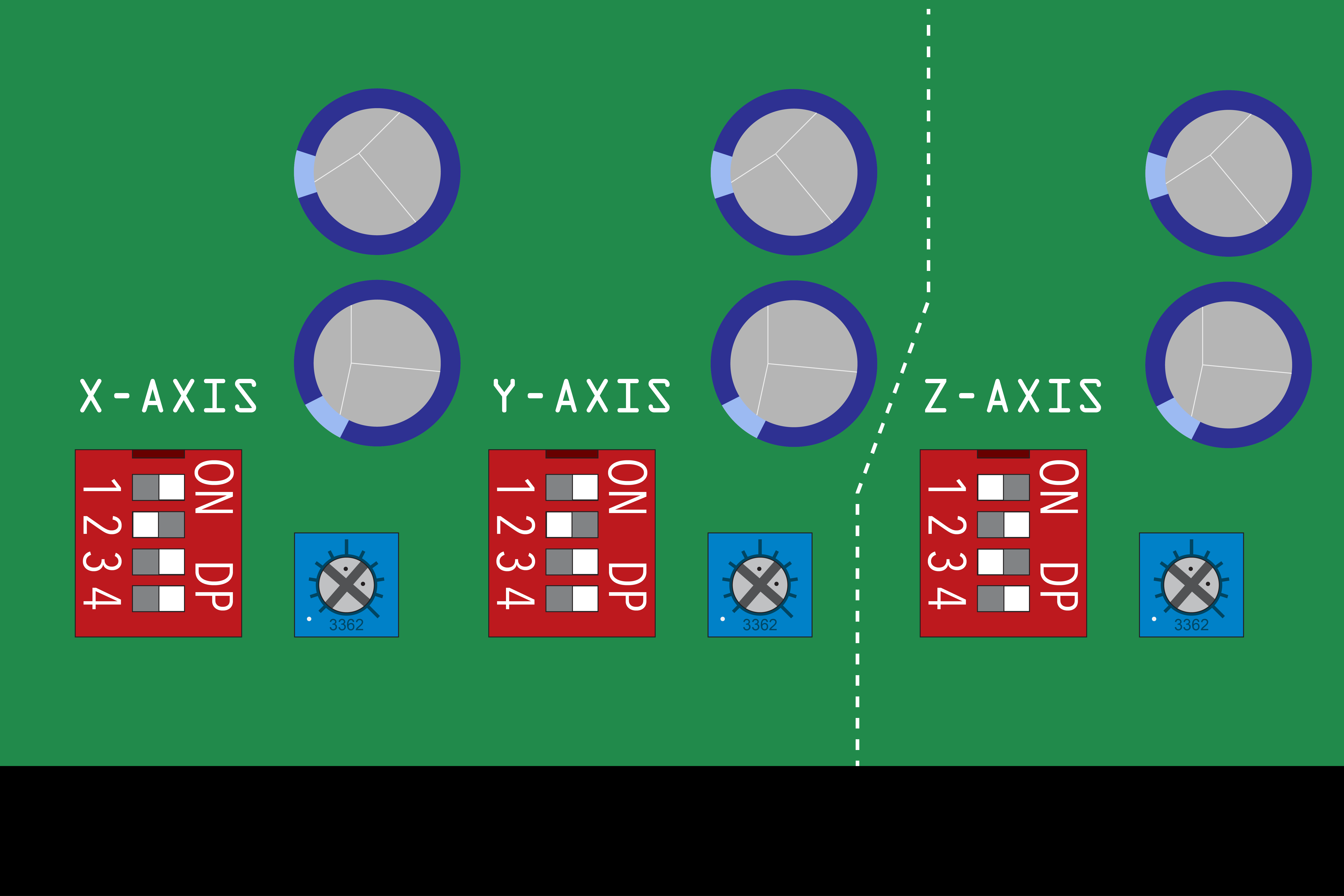

This is the Inventables recommendation (direct pull from the linked instructions page) and where mine are too:

Yup,

exactly where mine are set.

Also received ‘lube’, but didn’t know what for.

Justin,

Where did you end up setting your pots?

Did you go beyond the “2:00” setting?

The confusion stems from the fact that there are 2 sets of instructions for the XController on the website … one that was for the “upgrade” kit X-Carve Instructions: X-Controller Assembly

and the one that is mentioned above … X-Carve Instructions: X-Controller

I believe that when the XController was first announced a lot of users had both Y1 and Y2 wired into the same terminal (thus why pots had to be adjusted…) but if motors are wired individually into their proper terminal then there was no need for adjusting the pots.

I’ve had my XController since October with all motors wired to their proper terminals and haven’t needed to adjust any of the pots…

Just my $0.02 …