@RobertRay

When I started with the extended macro functionality, I first looked for an appropriate library.

I made my first attempts with GSHARP on github. From this time comes the syntax g#2g".

But it was not executable on Windows XP. Because I couldn’t find any other suitable library, I decided to program it myself. For me it was an estimation of the effort. I hope you understand that I can not reproduce the complete FANUC o-code programming. But if you have a certain wish, what you are missing, let me know. I will try to realize it.

Thank you for the explanation. 2 of the command that I thought would be helpful is the “GOTO” line number when working with the “IF” statement. Also I have tried to nest the “WHILE” command without any luck.

Ok, I’ll put it on my to-do list. I’m pretty busy right now. So please give me some time. But I’ll get back to you when I’ve got something finished.

There’s a plasma tube and plate cutter that almost do what I need. The vutter Head must rotate X and Y axes.

@AntonioCarlosFedatoF

I have created a new model type for your machine.

You can now download the beta version V3.47.3 from my website. It contains a machine example with the name “PlasmaCutter”. This is also the name of the new type.

Unfortunately there is a problem with the axis names. Your designations were for a lathe.

But in my program I have provided additional rotation axes only for milling machines.

I hope you can still use the new model type for simulation.

May I ask if you already have the necessary mathematics for the movements to cut the holes ?

Release notes V3.48

after my last trips to the multi-axis robots, I would like to concentrate on the 3-axis milling machines again.

For a long time now, the wish to be able to engrave has been on my list.

Especially the production of inlays is a very attractive task for a CNC machine.

Now that the first tests have been completed promisingly, I have created a new version V3.48,

which you can now download from my website.

The complete range of topics from the ‘simple’ engraving to the inlay cannot be documented in one video.

Therefore here is the 1st part, in which I introduce the principle of a V-cutter and the new function V_Carve.

Have fun with GrblGru

I like where you are going with this. Well done!

Hello, I just start to use GRBLGRU (3.44.0 and 3.48)

I have done a 2D part correctly

Now, I would like to made a 3D piece of wood.

I try to use the projection mode for do that but it don’t work.

steps:

- import the stl part

- draw a rectangle with the dxf template

- create a jog pocket of the rectangle (with the projection mode)(I have tested different pocket type)

but the result is not correct: the rectangle is not project on the stl part. If I change increment or depth (don’t let 0): it’s the same.

if I change the pocket to cut, the rectangle is correcty project to the stl part.

Could you help me ?

thanks

@L112

First of all, thank you very much for your feedback.

You’re right. This is a mistake.

On my WebSite is a new beta version V3.48.1, with which the error should be fixed.

Please note that straight lines have to be broken up into many small sections when projecting. You can change the size of the pieces with the parameter “Splitting size” (default = 2mm) in the settings. A smaller value increases the accuracy, but also the time for the calculation.

Thanks for your quick response. Your software is really interesting and easy to use.

Install v3.48.1:

I have tried to test but i have the error:

“Extract: error writing to file H2.stl”

After manually delete before the TOE folder, the install is now ok

I have just two problems after test it :

– the final 3d is not correct in dimensions.

- contour: I can’t change it with the offset parameter

- thickness: I can’t change it with the depth and sum of depth or splitting

– cheese or tetris part contour aspect: I can ameliorate a little with the stepover and using a litte tool but not enough.

Sorry for my questions, I’m a beginner to use cnc machine or tooling parts.

Do you have some ideas for have a correct 3d final part ?

@L112

If you answer yes to the question in the setup, the working directory will be deleted and everything will be reinstalled. Then you do not need to delete the folder explicitly.

I just checked it again. Both the offset parameter and depth/sum of depth work for me. Therefore I need more information. Can you please save me a project file and make it available to me here ?

You do not need to apologize for your questions. They help to improve the program. So please continue

I have send the file let me know if the file are corrupted

Release notes V3.49

once again I would like to announce a new version of my program.

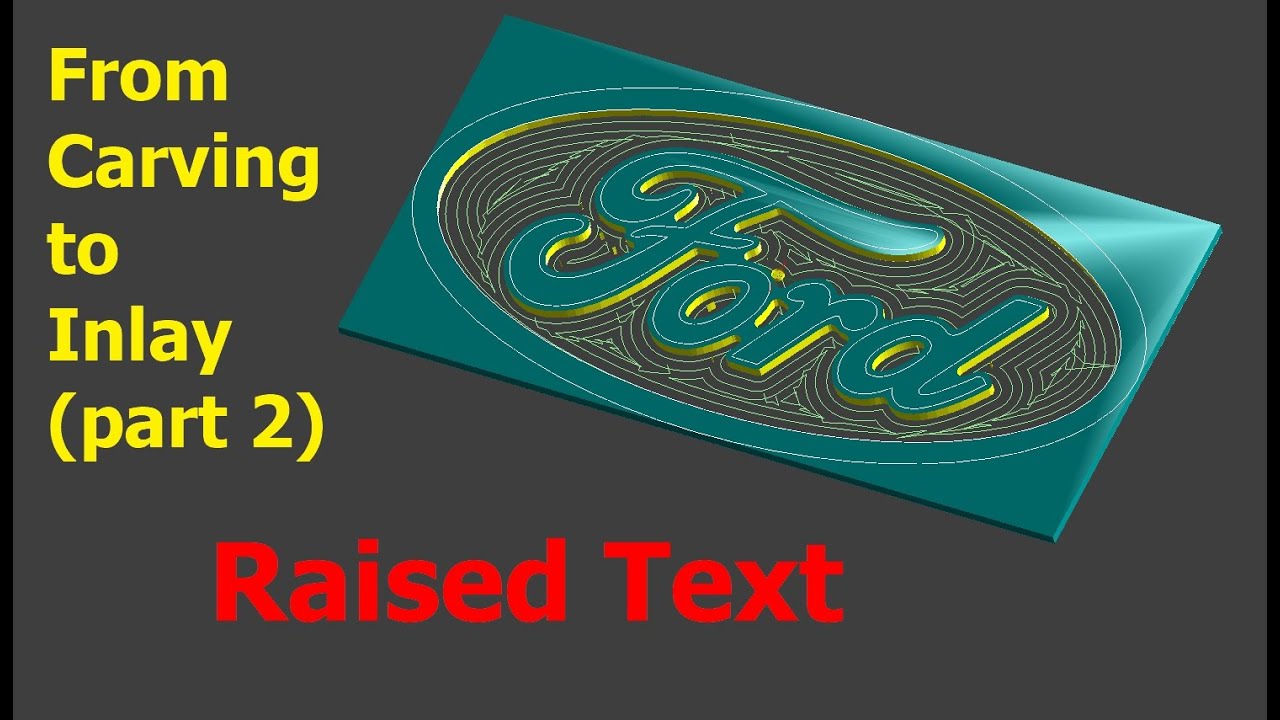

The attached video “From Carving to Inlay (part 2)” this time concerns the creation of raised text.

The reworked function “Pocket Contour parallel” for machining pockets with islands thus provides the basis for the production of inlays, which however can only be presented in the next version.

Nevertheless I hope that there is already something interesting for some of you.

Have fun with GrblGru

Greetings! On July 24, I posted a video about your program Самый НЕДОРОГОЙ токарный ЧПУ станок на Arduino /ProDIY - YouTube. I hope more people will learn about your wonderful program!

This is really a great video. I haven’t seen it yet.

Thanks a lot.

Grblgru, just want if you can help me about the CNC Lathe scan mode. I just put in work a Unimat SL with manual control assisted with CNCN and also the total automatic CNC mode with your great program. I want also do a video but need if is possible reactivate your old choice to the lathe scan surface once also I didi the scan tip and works great but not possible now with your software.

Thanks in advance and all the best.

Giovanni

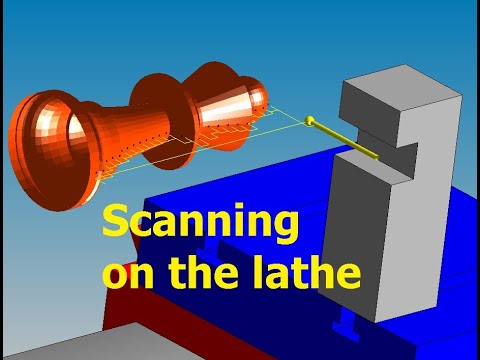

Beta notes V3.49.9

on my website is a new beta version V3.49.9. it contains the first attempt to make measuring on the lathe available again.

I have made a short video about it. It shows how to measure an STL object virtually. The calculated GCode can also be sent to the controller.

Unfortunately my probe is not working at the moment. Therefore I could not make any tests in practice.

Hi. Really appreciate a lot your collaboration to include again this valuable feature in your excelent program and tool. I appreciate your positive sense to help us to go ahead easily in this CNC world.

Thanks, thanks again.

All the best,

Giovanni

GRBLGRU is awesome - I have though discovered onme issue I dont understand.

When I export a DXF from a FreeCAD model, there seem to be some features missing after import in GRBLGRU. See attached screenshots - I doublechecked the correctness of the DXF in Autodesk TruView, its only in GRBLGRU where there is one of the pockets missing.