Which device or controller did you pick??o

I’m not very often here, I really would like to. If there is any bigger issue please send me the email so I will come here to help ![]()

We are buying X-Carve and we will prepare full documentation for the connection etc we are waiting for the X-Carve unit.

There is new version of the docking station where the pins names are in the same order now.

http://optlasers.com → CNC Lasers → Accessories

For X-Carve connection we suggest to use PWM output with 0-5 V together with our laser heads TTL/PWM input.

Analog input is designed to work with the 0 - 5V range and if 10V is connected for longer time the driver is heating up more. While working with S0 - S50% you are not exceeding 5V.

TTL/PWM input can accept even up to 24V so 10V form PWM output from X-Controller is perfect.

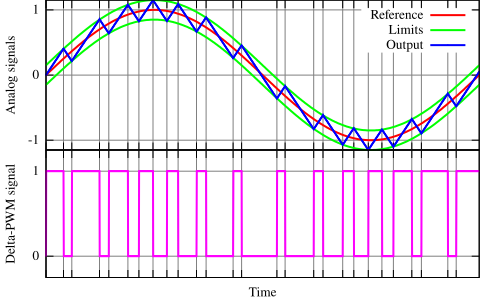

I got a nice question from one of the forum users, how TTL input can be used for grayscale if it is just ON/OFF feature.

If TTL signal is fast enough the output signal is averaged. So if we just switch ON and OFF the laser head and if it is done fast enough we can obtain “analog” signal and obtain grayscale. Below is perfect example taken from Wikipedia.

What doeas mean fast enough?

Most of engraving works is done with speed around 30 mm/s. If we take under consideration 0,2mm accuracy we have max 30/0,2 = 150 Hz frequency of switching on and off. It means that if we want to make dot, space, dot, space, dot, space and so on with maximum accuraccy assumed we will have to switch laser on and off the laser 150 times per second. Since PWM signal frequency is higher, even around 5000 or even 10000 Hz the laser power is averaged similar way like we bake pizza.

The big heated in the oven is switched on and off few times a minute maintaining the temperature inside, when it is switched on it works with full power, when switched off 0 power but anyway we can control the final effect - how much we want the cheese to be baked crispy. It is the same with wood and laser but we need to go into microscale, switch it on and off not few times a minute but 1000 or more times per second.

Hi! I’m wiring my new opt láser to my x carve, and I having some problems, can you send my a clear diagram of how to wire, using the ttl función please!

From the Arduino/gShield controller and the X-controller the PWM signal is 0 - 5 volts (and if using grbl 1.1f the frequency is 1 KHz).

The 0 - 10 volt signal from the X-controller is an analog 0 - 10 volts.

Hi!

TTL input from laser head is going stright to X-Controller TTL output.

@LarryM thank you for clarification. I corrected my post. 0-5V for TTL is finr, 0-10 and 0-24V also, every signal above 3,3V gives max output power. If PWM is used then signal is averaged.

I know that some people changed internet PWM base frequency in order to get better result. Did you try maybe to check if there is actually visible difference? Is it hard to change base frequency in X-Controller?

I have not tried it. It is easy to change the PWM frequency in grbl. You have to recompile, but that’s easy to do.

Which is the variable? I must be blind. I’ve Ctrl-F-ed config.h several times, but still can’t find it.

Looks like it’s in cpu_map.h

In cpu_map_atmega328p.h

// 1/8 Prescaler, 8-bit Fast PWM mode. Translates to about 7.8kHz PWM frequency.

#define TCCRA_INIT_MASK ((1<<WGM20) | (1<<WGM21))

#define TCCRB_INIT_MASK (1<<CS21)

@NeilFerreri1 , @LarryM thanks!

In the latest 1.1f, I found it in cpu_map.h

// #define SPINDLE_TCCRB_INIT_MASK (1<<CS20) // Disable prescaler -> 62.5kHz

// #define SPINDLE_TCCRB_INIT_MASK (1<<CS21) // 1/8 prescaler -> 7.8kHz (Used in v0.9)

// #define SPINDLE_TCCRB_INIT_MASK ((1<<CS21) | (1<<CS20)) // 1/32 prescaler -> 1.96kHz

#define SPINDLE_TCCRB_INIT_MASK (1<<CS22) // 1/64 prescaler -> 0.98kHz (J-tech laser)Just ordered the OPT xCarve kit, can’t wait.

Do I need to modify the firmware or factory newest firmware will work for PWM engraving?

You have two choices for laser enabled grbl versions (three if you want to use the older Jtech version).

I modified Inventables 1.0c to be laser enabled and you can get it here.

The other option is the latest official grbl release 1.1f which is available in the Inventables download area.

Most of the people that use my version do so because my version does not change the way any of the G-code operations are performed and because it can run at a higher feed rate than 1.1f which becomes an issue with higher powered lasers (> 4 watts).

Some prefer the “official” release but it has some “safety features” built in which modifies how some of the G-code commands work when using the laser mode. Several of the GUI senders have been modified to work well with 1.1f.

Some people have issues with the way that 1.1f handles the laser.

Either solution will work on the Arduino/gShield and the X-controller using the PWM feature.

Laserburn works the best i have found for my 6w laser from opt lasers and inkscape comes with a jtech gcode converter.

I’ve been following Lightburn’s blog and there’s some feverish activity going on, both in features and fixes. It’s a very ambitious project. I have a feeling this will be my laser software choice too.

Yes sorry my bad, stupid iPhone and me not checking it.

What are you trying to achieve with the laser?

Maybe I am missing out on something else my laser can do, it seems to cut and engrave very well with lightburn.

M4 only? Interesting.

Let’s keep this thread Opt Laser specific. I asked on this thread.

Hi Anthony I’ve some hard times trying to configure easel with OptLasers, and decided to try the lightburn. Do you have the screenshot with the initial parameters for it to work?

sold

I purchased the OptLasers PLH-3D-6W 6 watt laser a few months ago. When I initially hooked it up, I had it wired to the analog spindle output, but after reading this thread, I switched it over to the TTL output. It runs so much better now, and I have much better control of the laser wattage output for grayscale and full burns.

One thing that I have also done though is to use a IOT Relay to power my dewalt DW611 and shop vac for router use.

This is connected to the Spindle Analog output, while the laser connects to the Spindle TTL.

I built macros inside UGS to switch between laser mode (GRBL 1.1f) and spindle mode, and have the machine auto home and then reset zero for either laser or spindle use to the worksurface 0,0.

It works very well, and is simple to switch between laser or spindle usage.

When running in laser mode though, I end up having to disconnect my IOT Relay, because I end up getting EMF bounce back causing the xcarve to disconnect from my computer during periods of fast laser switching.

Would using a shielded pair for the IOT relay help with the disconnect issue, or should I just continue to disconnect the IOT Relay while using laser mode?

Also, is there a simple way to tap into the 24V power supply in the X Controller for powering the laser? I use a DW611, which is self powered through the IOT relay, so I’m barely using any of the available wattage for the 24V supply inside.

I’d love to be able to tap into it, but I also don’t want to modify the case of the x controller unless absolutely necessary.

Thanks!