So lately I’ve been working on a huge upgrade of my X-Carve. It was a 500x500 2015 machine that used the gShield and all original parts. The machine worked fine but I really wanted to upgrade the size. Well that’s where it started until I read @PhilJohnson walkthrough of his new controller and I though “Challenge Accepted!”

Now I thought it would be nice to write up a full post on what I did and what parts I used so anyone who is looking at doing any or all of these upgrades can see how I did it.

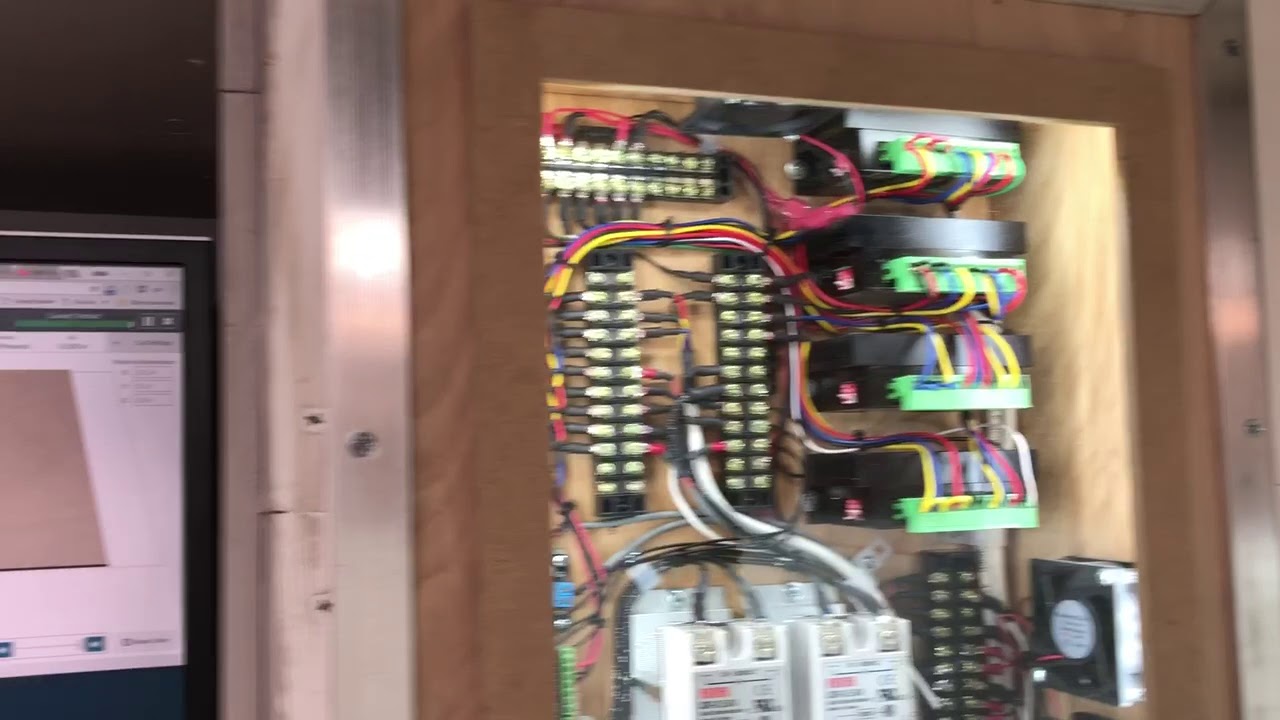

So I decided to do all the upgrades at once so I didn’t have to pull the machine back apart multiple times. So here’s the list of upgrades:

- Upgraded size from 500x500 to 1000x1000

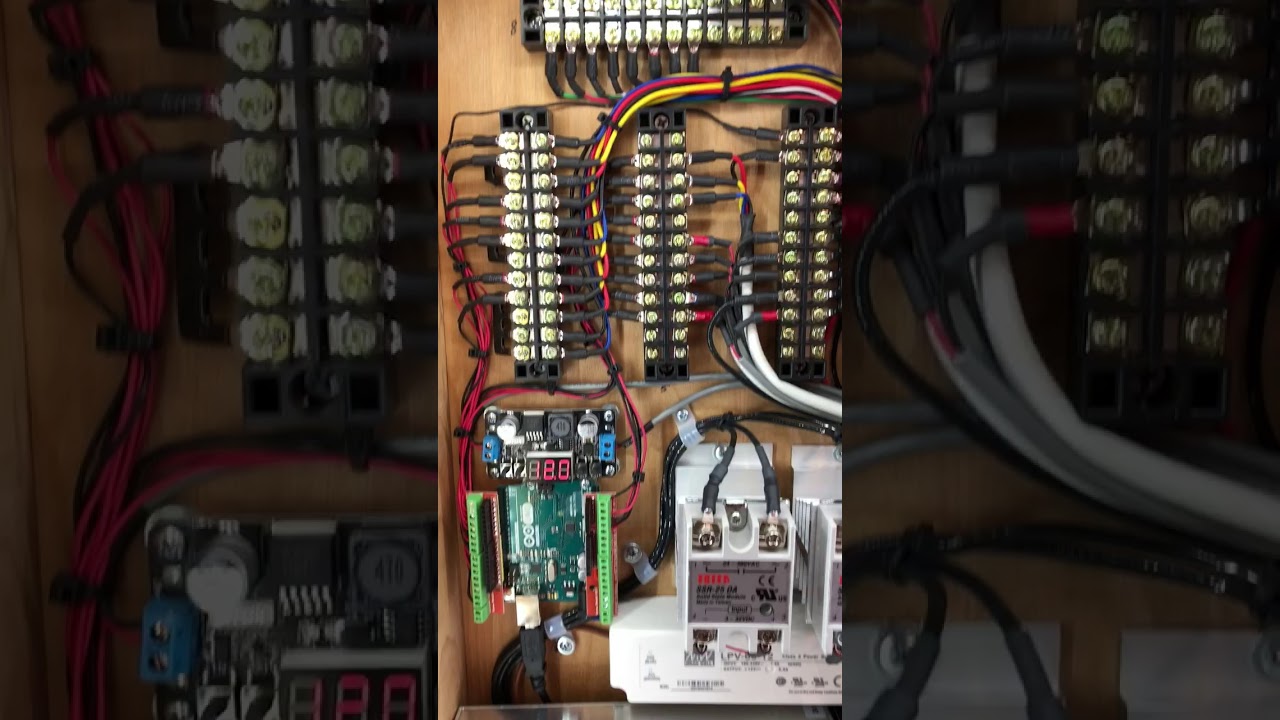

- Replaced gShield with ST6600 drivers

- Auto start spindle and shop vac

- Custom enclosure

- Upgraded motors from Nema 17 to Nema 23 (269oz)

- Upgraded belts from 6mm width/2mm pitch to 9mm width/3mm pitch

- Upgraded z-axis to CNC4Newbie1’s 6" linear rail (Coming soon)

- X axis Wide Makerslide

- Custom wasteboard with t-track

- SuckIt dust boot (totally worth it from my DIY version)

- LED lighting

- Full button panel with E-stop, Pause, Resume, Abort, etc.

- Computer nook with second screen

- Wireless Keypad Pendant

Below are some pics, video, schematics for the wiring diagram, and parts list

Pics

More pics at the bottom…

Schematic

xcarve schematic.pdf (96.5 KB)

Here’s the link to the parts list and additional pictures.

Before pics